Tytan polyurethane foam - a product of the American company Selena Co. S. A. Branches of the company are located in different parts of the globe, which allows you to keep an affordable price without loss of quality.

Russia has its own distribution network, which was launched in 1992. Over this long period, many fans of the brand have appeared.

Technical Specifications of Foam Titanium

Features of one-component polyurethane sealant:

- the frozen polyurethane foam withstands temperatures from –60 to +100 degrees,

- film formation on the surface of fresh foam occurs within eight to eleven minutes,

- the sealant is ready for primary processing (to cut) in half an hour to fifty minutes,

- it takes 24 hours to completely harden the foam,

- the density of the hardened sealant is 20-25 kg / cubic meter (at the cut - a homogeneous structure, finely meshed),

- the yield of foam from a standard 750 ml cylinder is forty-five liters.

Properties of polyurethane sealant:

- construction foam Titanium freezes under the influence of moisture,

- the sealant of this brand is resistant to moisture and mold, therefore it can be used for installation work in saunas, pools and bathrooms,

- foam has good adhesion to many building surfaces (even glass and metal),

- the hardened material has excellent thermal and sound insulation characteristics,

- the shelf life of the mounting foam is one and a half years,

- Vapors are harmless to the ozone layer and atmosphere.

Scope of the polyurethane foam Titan:

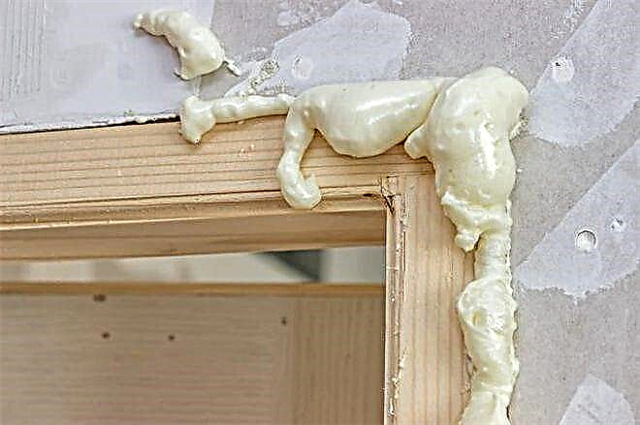

installation of window and door frames,

- thermal insulation and sound insulation,

- connection of building elements,

- sealing cavities of various sizes and in various materials,

- filling joints in roof structures and ceilings,

- gluing and insulation of wall panels, tiles,

- sealing and thermal insulation of water pipes, heating and sewer networks,

- connection and sealing of wooden structures from prefabricated prefabricated elements.

Features and Benefits

Tytan professional or pistol mounting sealant, unlike foam with a tube, is available in specialized cylinders equipped with threads for screwing on the metering gun. With the help of such a device, it is possible to apply the composition to inaccessible places. Using a gun, the builder will be able to quickly and accurately distribute the mounting mass. The use of such a sealant allows for large-scale construction work with minimal material consumption.

Any professional foams are used only in conjunction with a gun, due to which the master can perform the following actions:

- adjust the optimal dosage of the material,

- adjust the feed rate of the mounting sealant,

- it is economical to spend the product, since when the valve is released, the sealant is automatically cut off.

Unlike household foam, a professional one has higher technical characteristics, such as:

- good performance - from an aerosol can with a capacity of 750 ml you can get up to 65 liters of foamed mass,

- low secondary expansion, which eliminates the risk of structural deformation,

- high adhesion to any building products - suitable for aerated concrete, metal, wood, brick, concrete and other products,

- fast polymerization

- excellent soundproof performance (up to 61 dB),

- resistance to high humidity and fungus formation.

All professional formulations have increased primary expansion, which allows filling the average air gaps in one application.

Any type of polyurethane foam has some disadvantages. The disadvantages include poor resistance to solar radiation and precipitation. Due to the influence of such factors, the sealing joint may crumble over time and become unusable. Other disadvantages of the material include its toxicity. However, work with gloves and a respirator significantly reduces the negative impact of harmful fumes on human health.

The manufacturer of mounting sealants produces several varieties of Tytan Professional foams for professional use.

- Fireproof (products labeled B1). Its main feature is its resistance to ignition. Such material is able to not ignite and not melt during a fire for 6 hours. And also a one-component fire-resistant mass is able to reliably isolate the room from gas penetration and smoke.

- Winter - This is a two-component foam designed to work in extreme conditions. It can be used at temperatures from -20 to +35 degrees. An improved composition formula allows not to heat the container before use and during the sealing process.

- Summer - it is a foam designed for use at positive ambient temperatures. These materials do not contain harmful components that have a destructive effect on the ozone layer.

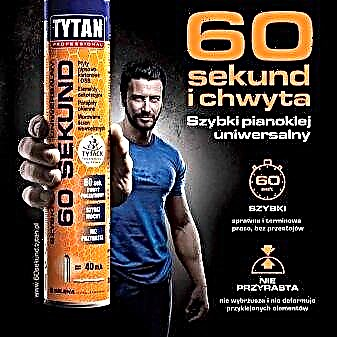

And also the manufacturer produces 60 glue foam. This is an innovative material designed for quick and easy installation of building products. It is used when gluing decorative elements, ceramic tiles, mineral wool, drywall, OSB boards, aerated concrete structures. Glue foam can stick the product in 1 minute. Such material is easy to use and versatile. It can be used at low temperatures or high humidity. Glue is applied with a gun. Complete polymerization of the applied mass occurs in a day.

Scope of application

Professional polyurethane foams are universal materials. They are widely used in repair and construction activities.

Such sealants are intended for the following tasks:

- sealing of various voids and seams with a size of more than 20 mm. The use of foam eliminates gaps in the roof, around pipelines and other building structures. The result of the use of such a material is the absolute tightness of the seams and air gaps,

- installation and fixation of door frames, window openings, balcony frames, wall panels, roof tiles. With sealant foam, there is no longer any need to use dowels or anchors to fasten various products,

- warming of cold rooms. With the help of foam, it is possible to strengthen the sheets of thermal insulation material, while not reducing the heat transfer of the system,

- improvement of sound insulation of construction sites, car bodies.

Fire foam is often used when installing fireproof doors. A seam made with sealant will not let smoke into the room. When exposed to fire on polymerized foam, it will not melt, release harmful substances to human health.

Where applicable

Tytan professional tools are universal. They can be widely used for large-scale work at production facilities and at home.

Polyurethane foams have found their place in solving the following problems:

- Sealing of cracks, seams, voids, joints more than 10 mm. They help to remove gaps in structures indoors and outdoors, including the roof. The result of using such a sealant will be high-quality insulation from moisture, noise, smoke.

- Fixing apertures, frames, panels, doors, tiles. With the composition there is no need to use dowels for additional fixation.

- Warming. The tool can create additional thermal insulation between the sheets without affecting the heat transfer.

Refractory composition can be used for fixing fire doors. The created seam will not allow smoke to enter the room. Under the influence of fire, the foam does not melt, which eliminates the harmful effects of toxic fumes.

Recommendations for use

How to use Titanium foam to get the desired effect:

- Before use, the balloon is well shaken, which increases the yield of the foamy mass by mixing the components.

- Before applying the surface requires preparation. It is necessary to clean it from dirt and dust. It is also recommended to moisten it with water using a spray bottle. Such operations will speed up the solidification process and improve the quality of the sealing result.

- When applying foam, the cylinder should be kept bottom to top.

- Before work, you need to adjust the speed and volume of the mixture output.

Professionals recommend working with foam so that it does not accidentally get on the skin. For this you need to have gloves, a mask, long sleeves. You also need to protect your hair, otherwise it will be very problematic to remove foam from them.

It is rational to seal the joints with foam if their depth is not less than 10 mm. For smaller seams, completely different means are already used. Work should be carried out at a temperature of +5 to +30 degrees. The humidity should be no more than 60%.

Filling gaps is done only on a third of the volume. Vertical slots are processed from bottom to top. Excess foam should be removed after drying, that is, after 6-8 hours. If you do this earlier, the seal may be broken, in addition, it will be completely inconvenient to do this, not frozen foam stretches.

Reviews

Tytan Professional is a brand owned by a large firm Selena Co. S. A. The company produces high quality construction products that meet European standards. Specialists constantly monitor the quality of the goods, monitoring consumer demands. Titanium mounting foams are widely known throughout the world.

The Tytan Professional line receives positive reviews from large organizations and private masters. Deficiencies can be found in any material, but mounting foams from a well-known manufacturer meet the requirements, with the right approach to them there are no problems. The company has factories in all countries, and the consumer receives the product at an affordable price.

Range of polyurethane foams Titanium

The entire range can be combined into three groups:

1. One-component household foams (have plastic applicators for applying foam).

2. Professional sealants (Tytan Professional polyurethane foam is recommended for installers, requires the use of a gun).

3. Special sealants (they are needed for installation work in special areas, for example, Tytan B1 polyurethane foam is fireproof, designed to work in fire hazardous places).

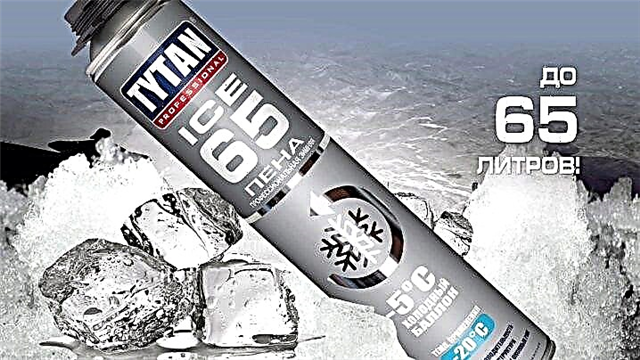

In addition, the first two groups have winter and summer options. Sealants with an increased yield of the substance from the cylinder are indicated by the number 65. For example, Tytan 65 polyurethane foam.

To cure all types of foams, you need to moisten the surface. Winter sealants should not be applied to a seam filled with ice or hoarfrost. All Titanium foams have antifungal and anti-mold components.

Possible difficulties and problems

1. Foam does not stick in the cavity, falls or drains.

The reason is the ambient temperature is lower or higher than the set limits. Foam loses its ability to adhere.

2. The hardened foam begins to crumble after six months or a year.

The reason is that the material is not protected from ultraviolet and other aggressive environmental influences.

3. Wet rod.

The reason is that the curing time of the foam was chosen incorrectly, the ambient temperature is too low.

4. The hardened mounting foam shrinks.

The foam was too hot. Subsequently, when cooling occurred, the pressure in the pores decreased. Shrinkage has occurred.

Reviews about the polyurethane foam Titan positive. But no one is safe from fakes, violations of storage conditions at retail outlets.

How to use?

The process of using Tytan Professional Foam includes the following steps:

- before use, the foam bottle is shaken vigorously, which helps to mix the components and increase the yield of foamy mass,

- the cap is removed from the cylinder, and the dosing gun is screwed in its place,

- before applying sealant to the surface it must be prepared. The working plane is cleaned from dust and dirt. Experts also advise wetting the surface with water using a spray bottle. Such actions will accelerate the polymerization process,

- when applying foam, it is recommended to keep the balloon upside down,

- Before starting work, it is necessary to adjust the optimal dosage of the composition from the tank. For these purposes, it is necessary to adjust the volume and output rate of the sealant using the valve located on the metering gun.

When using polyurethane foam, the following recommendations should be followed:

- it is necessary to work in special protective gloves, preventing the mass from getting on exposed skin,

- seams with a thickness of less than 10 mm should not be sealed,

- works are recommended to be carried out at a temperature from +5 to + 30 ° C and relative humidity of more than 60%,

- air gaps are filled only on 1/3 of their volume,

- filling vertical openings is best done in the direction from bottom to top,

- excess foam is allowed to be cut off only after the mass has completely cured (at least 8 hours must pass).

Subject to these rules, you can count on conducting quality construction work.

Range

When buying polyurethane foam, it is necessary to determine in advance the scope of work that needs to be performed. It is also best to roughly estimate the amount of material that will be needed. Tytan's range of polyurethane foams is represented by a wide range of products for various types of work. You can divide all products into three main groups:

- One-component formulations are sold with a plastic applicator, which eliminates the need for a gun.

- Professional formulations are designated Tytan Professional. Cylinders are prepared for use with a gun.

- Special formulations are used in individual cases when it is necessary to obtain any specific properties from the hardened foam.

Studying various types of Tytan polyurethane foam, it is worthwhile to pay attention to Tytan-65 foam, which differs from other varieties by one of the highest exit rates of finished foam from one cylinder - 65 l, which is indicated in the name.

Tytan Professional 65 and Tytan Professional 65 Ice (winter) are some of the most common options. In addition to a large amount of ready-made foam, several more distinctive properties can be distinguished:

- ease of use (the cylinder is prepared for the use of a gun),

- has high sound insulation - up to 60 dB,

- it is applied at plus temperatures,

- has a high fire resistance class,

- Shelf life - one and a half years.

Tytan Professional Ice 65 differs from many types of polyurethane foams in that it can be used at low temperatures: at -20 air indicators and -5 cylinder indicators. Thanks to the use of innovative technologies, even at such low temperatures for work, all properties remain at a high level:

- Productivity is about 50 liters at low temperatures, with an air temperature of +20 ready-made foam, you get about 60-65 liters.

- Sound insulation - up to 50 dB.

- Pre-treatment is possible in an hour.

- There is a wide range of application temperatures: from -20 to +35.

- It has a middle class of fire resistance.

When working with Tytan 65, it is necessary to clean the surface of ice and moisture, otherwise the foam will not fill the entire space and lose all its basic properties. The product easily withstands temperatures up to -40, so it can be used for outdoor work in the middle lane or more southern territories.

After applying the foam, it must be remembered that it will collapse when exposed to direct sunlight, so it must be used between building materials or painted over after solidification.

Using professional Tytan 65 polyurethane foam allows you to achieve excellent results: one cylinder will fill a large volume, and the use of a special composition of Tytan Professional Ice allows you to carry out work even at low temperatures.

For more information on TYTAN 65 foam, see the next video.