Aerosol varnishes are a special type of varnish mixtures that is simple and easy to use. Nevertheless, whoever first encounters the need to use such materials is very surprised to learn about the number of existing options for coloring compounds. Therefore, acquiring such materials, it is worthwhile to familiarize yourself in detail what types of varnish in the cans exist and what their differences lie in.

Benefits

Aerosol varnishes, regardless of manufacturer, have several advantages.

- These compositions do not require dilution and mixing, they are ready for use from the moment of their acquisition. To work with spray cans, you will not need extra waste on additional tools: brushes or rollers. Spray varnishes are available in small-volume cylinders, which makes them practical and mobile material.

- Aerosols in spray cans are often a type of quick-drying coating product. Drying time is several minutes. Due to this property, smudges do not form on the treated surface.

- Spray varnishes are designed for spraying on various surfaces, such as metal, brick, wood, plastic. They can cover both flat surfaces and inaccessible places, all kinds of protrusions and bends, for example, sections of the machine that need to be updated, but it is very difficult to reach them. A striking example is the ceramic two-component varnish “CERAMIC”, which gives the surface a noble shine, protects the painted surface and increases its wear resistance.

- Varnish mixtures in cylinders are very easy to operate. In order to use them, certain skills, experience and special working conditions are not required - just read the instructions for use indicated on the cylinder. The expense of funds will be minimal - this type of coating material is considered the most economical. The coating layer will be uniform and uniform.

- These coatings have an affordable price, although they are more expensive than conventional paints and varnishes.

Any varnish spray has excellent physicochemical characteristics, is highly resistant to moisture and various aggressive substances, as well as stability to temperature extremes. The surface painted by these means is considered completely protected from various types of mechanical and atmospheric influences.

Varieties

There are several varieties of varnishes. Of these, two types of water-based are worth highlighting: acrylic and polyurethane. The advantage of these sprays is their fire safety. In addition, they dry quickly enough, create a durable coating, practically do not have a specific caustic chemical smell, unlike paint.

Polyurethane

Polyurethane varnish is a derivative of polyesters and diisocyanates. Such a coating is resistant to physical influences. It is divided into two types: one-component and two-component (in aerosols only one-component compositions are used). May be water based or alcohol-based.

Advantages of polyurethane varnishes:

- due to its composition they do not form cracks after complete drying,

- do not exfoliate

- create a durable coating

- resistant to aggressive environments and UV rays.

Acrylic

Acrylic varnish is a viscous water-soluble liquid, almost odorless. It is made of liquid polymer or the so-called acrylic dispersion.

This coating has the following physicochemical properties:

- drying occurs due to the evaporation of water, after which the coating forms a film capable of protecting it from various mechanical damage,

- after drying, the coating is not influenced by any kind of liquid,

- acrylic film retains transparency and does not turn yellow under the influence of UV rays,

- can be applied to any surface, including brick and concrete,

- possesses high adhesion with well cleared surfaces.

Nitrocellulose

Nitrocellulose lacquer is a compound of resins, colloxylin based on an organic solvent. It has a pungent odor, after drying it becomes safe for health. It can be used inside the living room - subject to careful ventilation. The drying period is one hour. Aerosol creates a durable coating with excellent protective characteristics, has excellent decorative qualities.

Based on external characteristics, varnishes can be colored or transparent, matte or glossy. There is also a reflective aerosol that is discarded by particles of light from glossy surfaces. Which product to choose for the job is the business of every customer. It all depends on the place of application, the type of surface to be painted and the expected results.

Application area

Regardless of the manufacturer, the composition of the spray varnish, these sprays have a very wide scope.

Conventionally, there are three main areas of use of varnish-spray.

- Automotive industry. The composition is most often applied to matte paints in plastic and chrome.

- At home. The universal composition can cover various pieces of furniture, accessories, accessories, toys, give shine to various surfaces, thereby creating works of art.

- Construction industry. Widely used to cover various surfaces.

Application Features

Apply varnishes in spray cans without having a certain experience with them.

It is enough to follow a few simple recommendations.

- Shake well before use for 2-3 minutes. Its internal contents can be sprayed to the surface if the sound of a ball is clearly audible inside the can.

- Before starting to cover the surface, the varnish should be sprayed in an inconspicuous place for the sample. If the painted surface has a black outer layer, then you should not worry: the appearance of the product after spraying the product will not suffer.

- Spray to the surface with an aerosol from a distance of about 30 cm, the spray can must be kept upright.

- Apply the aerosol chemical in a uniform layer. If necessary, you can re-apply the coating, but only after a 10 minute pause.

- If a small amount of varnish is needed to cover the surface and the entire contents of the spray can not be used, then the remainder can be left the next time. However, the spray gun must be cleaned. To do this, turn the can down and spray until the jet disappears.

Before starting the painting, you should study the instructions and then strictly adhere to the basic safety rules:

- when using organic varnishes, ventilation is mandatory,

- do not spray the can near open flames,

- it is necessary to have overalls, a mask for respiratory protection, goggles, gloves.

Water-based aerosol formulations do not require such strict safety precautions - in this case, the use of masks and glasses can be excluded.

After finishing work, you must wait until the surface is completely dry. At the same time, care must be taken to ensure that dust does not get on it during drying, and try to protect it as much as possible from possible mechanical damage.

The following video introduces you to a brief video review of HB body acrylic clear coat.

Advantages and disadvantages

Aerosol varnishes are characterized by a lot of advantages. Almost all types are immediately ready for use. They do not need to be mixed or bred. No need to have additional tools, no brushes, rollers required. You can save money on the purchase of tools and solvents, while using varnish can be in various conditions.

Drying time is usually indicated on the spray can.. As a rule, varnish dries quickly. Therefore, on a steel, plastic or wooden plane leaks will not have time to form.

The composition can be used for planes of various shapes. Regardless of whether the surface is flat or curved, it will be evenly coated.

Even beginners can use varnish in the form of a spray. It does not require special experience and knowledge. The consumption of this composition due to the unique shape will be minimal. The layer will be continuous, without smudges. Since such varnishes are predominantly transparent, the original color of the coated material will be preserved.

They are able to withstand exposure to steam, moisture and heat. These compounds are not afraid of detergents and aggressive substances.

If you use them for steel, plastic, wood and ceramic surfaces, you protect it from mechanical damage and burnout in the sun.

In this case, you have the opportunity to get a glossy or matte surface.

The material in the cans has an affordable cost. At the same time, you can buy a small amount of coating. Liquid formulations are usually sold in large containers. Not every cylinder is of high quality.

The disadvantage is the fact that it is necessary to strictly adhere to the dosage during use and do not apply varnish in a large layer. Otherwise, the coating quality may deteriorate. In this case, the layer will dry for a very long time.

The spray torch must be uniform. If the gas pressure in the can is insufficient, spraying problems may occur.

Where is it used?

The varnish coating in the cans has a wide range of applications. The universal demand is most in demand. It is relevant when it is necessary to perform work on a small area.

You can highlight the most common areas of use:

- Automotive industry (used after body repair).

- Universal composition It can be used for kitchen accessories, bath accessories, furniture, decorative elements.

- The construction industry and the electrical industry. Often, glossy and matte varnish in cylinders is used here.

Glossy or matte

Gloss is best suited for dark surfaces, as it allows you to get a spectacular shine. Use such material for furniture decoration.

This type of coating emphasizes the pattern and contrast of the lines. However, mechanical damage on a glossy surface will be more noticeable.

The strength of the processed material does not depend on whether a glossy or matte spray will be used. This parameter is affected by the manufacturing quality of the composition. The best properties are usually characterized by expensive models.

Matte spray can simplify the cleaning process, as it needs minimal maintenance. This varnish is used when it is necessary to achieve a natural coating of the paint.

Careful grinding of the product will make the final result more aesthetic.

Transparent or color

Transparent models are in greatest demand because they are universal. Thanks to this composition, you can consider the natural pattern of wood. You can use a similar varnish on different types of wood. It is better to use a transparent version on expensive species (for example, oak, beech). Colored aerosols are best used on cheap wood.

Such material allows you to solve several problems, he:

- improves the color of the paint,

- creates a noble expensive appearance,

- protects the surface from damage.

Today, you can purchase varnish in various shades. You can choose the composition for any interior. The most popular is the white and black color of paint in spray cans.

Using white, you can process parquet and light surfaces, black will create a touch of luxury.

When buying, you need to consider 2 parameters:

- Absorbency. Water-based coating is not characterized by deep penetration.

- Shine. The larger it is, the darker the surface will look.

In the next video, you are waiting for an experiment using varnish in a spray can.

5 Motip Clear Varnish

Buyer Choice

Country: Germany / Holland

Average price: 320 rub.

Rating (2019): 4.5

Automotive varnish is created using an acrylic base and has high transparency. Available in the form of aerosol cans with a capacity of 0.5 liters. This volume is quite enough to process up to 2 m² of body surface. It perfectly updates the varnish layer of the car and is suitable for laying on chrome paint or with a metallic effect.

Aerosol varnish has better adhesion to the painted surface of body parts. The applied layer is resistant to ultraviolet radiation and weather fluctuations, demonstrating high strength and durability. The popularity of Motip Clear Varnish in the domestic market confirms its practical properties and versatility. Varnish is often used not only to update the car body, but also when processing various decor items, furniture, etc. The supply of material in a ready-to-use form (in cans) makes the process of applying a protective layer not difficult and quick.

4 Mobihel Anti-Scratch HS

Small scratch resistance

Country: Slovenia

Average price: 1452 rub.

Rating (2019): 4.6

The products of this brand on the market have a reputation for quality and balanced products, which have a number of advantages over competitors. Two-component varnish based on acrylic resins is highly transparent. Preparation for work with the hardener allows you to get the material of optimal viscosity. As a rule, two (three) layers of varnish are applied to a painted car body with a shutter speed of no more than 15 minutes. It dries quickly enough, with the right consistency does not leave streaks and requires minimal polishing.

The resulting protective layer is resistant to external aggressive environments and temperature fluctuations, has a high resistance to mechanical stress (demonstrates the best resistance to minor scratches). The base enamel coated with MOBIHEL automotive varnish remains in its original color, and the coating itself retains its properties over time.

3 PPG D800

The best ratio of price and quality

Country: Italy

Average price: 950 rub.

Rating (2019): 4.8

Specially designed for body repair painting, PPG D800 varnish is based on acrylic and polyurethane resins. Initially, being a topcoat, it is in its characteristics completely inferior to the factory color, giving any car a fresh attractive look. The varnish retains its transparency (does not turn yellow) and lays on the surface with an even layer, the properties of which remain unchanged for a long time. This coating tolerates grinding and is not susceptible to harmful environmental influences.

The automotive paint PPG D800, being a product of the premium segment, meets all quality standards and justifies the characteristics declared by the manufacturer. Using this tool in combination with various additives (plasticizers or composites), you can get a completely original texture with the effect of leather, suede, or a matte surface without gloss. This technology will change the look of the car, giving it more personality.

Color or transparent?

Most often, transparent varnish is used in spray cans. This is due to its versatility. It is absolutely invisible on the surface, through it you can see the natural pattern of wood.

It can be used on expensive wood:

Cheaper wood species often use colored aerosols. This option can solve several problems.

Colored spray varnishes allow you to:

- improve the color of the paint,

- protect the surface

- create a noble expensive look.

On sale there are a huge number of different colors. You can choose a varnish for wood for every taste and for any interior.

When buying, you need to consider the following characteristics:

- absorbency - for example, water-based products do not penetrate so deeply,

- shine - the more it is, the darker the surface looks.

It is quite difficult to get rid of bright areas after using colored aerosol on a dark surface.

The most popular colors are black and white. The first option will create a touch of gloss and rigor. White colors are ideal for light surfaces and parquet.

2 Bosny VG

Best shine

Country: Thailand

Average price: 500 rub.

Rating (2019): 5.0

This is one of the best varnishes in aerosol cans. The material is applied over the existing coating, preserving the shades of the original color due to its perfect transparency. At the same time, a special composite in the varnish composition provides high reflective characteristics of the applied layer, which gives a completely new look to the automotive surface, despite the full color identity.

Spray varnish is the most versatile product and can be used not only to update the appearance of a car. It has excellent adhesion and evenly lays on metal and wood surfaces, glass, paper or plastic. Subject to the rules of storage and use, Bosny varnish is completely safe for humans. Carrying out painting work with an aerosol spray can is a surprisingly simple and easy task that does not require special skills.

1 BRULEX 2K-HS

High quality material

Country: Germany

Average price: 1278 rub.

Rating (2019): 5.0

High-quality transparent varnish based on acrylic resins is made by the German manufacturer BRULEX using modern equipment. The resulting two-component material is excellent for full or partial coverage of the car body. Due to its good fluidity, a kit (1 liter of varnish and 0.5 liter of hardener) is enough to apply 1.5 coatings on a middle-class sedan. The drying time to complete polymerization is one day, but this process can be carried out in just 2 hours, if you work in a spray booth with heating. The surface temperature of the body parts should be about 60 ° C.

BRULEX 2K-HS car paint is very durable and does an excellent job of protecting the paint from the environment. Due to the balanced composition of the raw materials and the characteristics obtained, the applied layer retains its original luster for a rather long time. This material is made for professional repair, therefore, the quality of the coating can not be compared with the varnish layer applied with aerosol cans.

Attention! The information above is not a buying guide. For any consultation should contact the experts!

Tips & Tricks

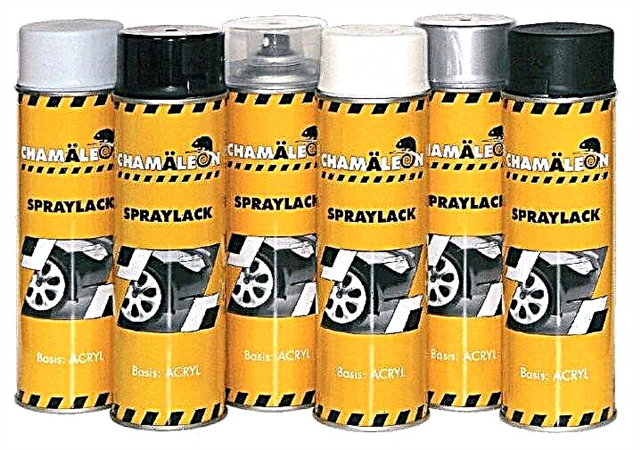

Popular brands of varnishes are as follows:

- Mobihel 1K. Used for painting cars. It forms a dense layer without sagging. Transparent, applied over the paint as a topcoat. Dries completely in 60–90 minutes.

- Brulex Acrylic spray varnish, creates a decorative glossy coating on surfaces made of wood, metal and plastic. Dries in the air, does not turn yellow.

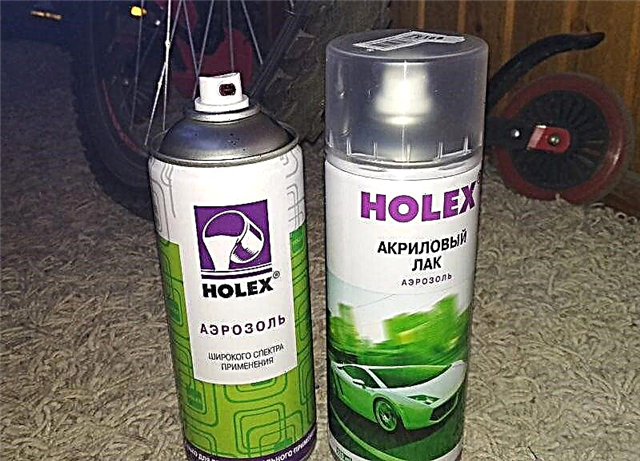

- Holex. Acrylic spray for painting the body, dries quickly (less than an hour). Very persistent, does not get cloudy.

Before applying, it is better to practice in an inconspicuous place, especially if the work is performed for the first time. Do not forget to shake the bottle with varnish before use, so that the composition is uniform. A respirator and protective gloves should be used in the work area, as many varnishes contain toxic solvents. These tips will help to varnish with an excellent result and is safe for health.

How to store the composition

Not always a high price indicates the quality of products. Sometimes branded aerosols can actually be fakes. Such situations arise when purchases are made in markets and stalls. Also, aerosol varnish may not be suitable for use due to non-compliance with storage conditions.

The average shelf life of paint materials is about 2 years. However, in reality, it may be less if the aerosol was stored in an improper way.

All recommendations for storing the spray are on the label. Particular attention should be paid to the permissible temperature difference. This criterion can tell whether it is worth buying a product in a given place.

For example, on the market all bottles with varnishes are stored at ambient temperature. In winter, it can reach 20 degrees. At this temperature, the aerosol will become unusable in a few weeks, will lose the necessary qualities. When using it, clouding on surfaces is possible, and peeling of varnishing may occur soon.

Exposure to too high a temperature is also detrimental to varnishes in aerosol cans. If you store it in the summer in the open, the hardener will begin to thicken. This will lead to the absolute unsuitability of the product in a month.

Therefore, it is best to purchase paints and varnishes in specialized stores. The main criterion for choosing should be the conditions that are created for its storage. Of course, price and manufacturer also matter. Budget options will have lower paint quality.

Storage rules

Expensive mixtures are not always of high quality, there are cases when branded spray cans are faked, especially fakes are found in stalls and on the market. In addition, if storage conditions are not followed, then the varnish mixture will lose its characteristics, and may be unsuitable for use.

Attention! The average shelf life of varnish materials is approximately 2 years, but this period can be significantly reduced if the varnish was stored in the wrong conditions.

Conditions and recommendations for storage of the can are written in the instructions or on the label. The main criterion is the storage temperature of the spray for cars or for wood. Given the temperature, you can understand whether it is worth buying products in the market, in a stall or in a store. For example, cans are stored on the market at air temperature; in winter, the temperature sometimes drops to -20 degrees. This temperature adversely affects the mixture in the can, which will become unusable after a couple of weeks. If you apply such a varnish to the surface, then it may become cloudy, and very quickly begin to exfoliate from the base.

High temperatures also badly affect aerosol cans. If in the summer at a temperature of 30-35 degrees to keep the can in the open air, the mixture will thicken, which will lead to its unsuitability after one month. Therefore, it is much better to buy varnish products for cars in stores where the best conditions for storage are created.

Aerosol spray can

The concave bottom protects the cylinder from high pressure. Inside, there is paint (varnish) and inert gas, and a tube passes through which the paint comes up. It ends with a spray head with a valve, the latter does not allow the medium to exit before being pressed.

The varnish in aerosol form contains a sufficient amount of diluent (solvent), so it is sprayed with very small drops. But liquid varnish can be applied in several layers, which gives a better result.

Colored and transparent varnishes

Transparent varnish is the most popular in car repair and furniture production. It does not need to be additionally tinted, it will not change the color of the main coating and will not hide the natural beauty of the tree. Transparent varnishes are indispensable for coating rims, headlights, as well as expensive varieties of wood - oak, beech, mahogany.

Colored varnishes are often used for cheaper types of wood. They help:

- enhance the brightness of the paint,

- protect wood

- give the product a noble appearance.

Most often, shades are used for different types of wood, as well as white, beige and black. Light paintwork materials cover the parquet, laminate, furniture to improve the appearance, gloss. When buying a product, it is important to take into account the penetration depth and the degree of gloss (the surface will look darker from strong gloss).

Tinting varnishes for car bodies should have increased strength. Suitable for these purposes 2K glossy and a series of varnishes brand KUDO. There are specialized products in headlight spray sprays (for example, Lens Clear HB Body headlight spray varnish).

Of the colored matte varnishes, Auto Dip liquid rubber should be noted, providing incredibly rich, vibrant shades. To improve the aesthetic properties, glittering agents and reflective additives are used. But, as a rule, they are used for painting bicycles, motorcycles, ATVs, as well as helmets.

Proper storage

If storage conditions are not followed, the varnish will quickly deteriorate. Usually, the shelf life of a quality product is at least 2 years, but violation of the conditions reduces this time. You need to carefully read the label, which indicates the storage parameters of paintwork materials.

It is especially important to clarify the ambient temperature. Prolonged freezing renders most varnishes unusable. The product becomes cloudy, and application to furniture or the car body will lead to unpleasant consequences. Prolonged storage at high temperature causes the hardeners to thicken, and after 1-1.5 months the cylinder will have to be thrown away. The recommended temperature range must be strictly observed, then the varnish will remain fresh for a long time.

Conclusion

Car varnish is the last to be treated as a topcoat. Therefore, the degree of protection of the vehicle from adverse factors and its impeccable appearance will depend on the quality of the composition and the correct implementation of the application technique.

Popular brands: Mobihel 1K, Brulex, Holex, Brulex, Carfit, Body clear coat, PPG D800, BOSNY VG, BRULEX 2K-HS.