Ceramic granite is one of the most durable finishing materials. It is widely used in residential construction. The material is intended for facing commercial, industrial, public buildings, for performing outdoor works and solving specific problems that other “ceramics” cannot handle. Characteristics of materials for these purposes are different. This is due to different requirements of consumers.

Type of flooring made of ceramic granite

One of the main parameters of this material is its geometry. Obviously, the shape and dimensions of porcelain stoneware on the stairs and the decoration of the walls in the kitchen are different. By the ratio of height to width, square and rectangular varieties of products are distinguished. They are convenient to install, economical, and cost a minimum amount of waste to trim.

Depending on the area, the following formats of ceramic granite are used:

- large - suitable for decorating large areas. It is characterized by high installation rates, has a minimum length of seams and, accordingly, is maintainable. Due to the large finishing area, such ceramic granite is suitable for rooms with high humidity, high “cross-country ability”. Large-sized porcelain tiles for walls and floors are in demand in technical, commercial, public buildings, but can be used in everyday life,

- small - suitable for domestic use, as it fits well into rooms of a small area. Also, this option is suitable for rooms with increased loads, since in the case of loose installation, small tiles better perceive pressure from equipment or heavy furniture. In the case of operational cracks, small elements are cheaper to replace, which is taken into account when decorating rooms with a large flow of visitors.

Large ceramic granite finish

Manufacturers produce a wide size range of ceramic granite from 5x5 mm to large-format plates with a side of 500 mm. The maximum size of porcelain stoneware produced by modern enterprises can reach 1.5x3.0 m. Such formats are considered an exception and are used to implement specific projects.

- 30x30 mm is the most common type of ceramic granite, which was one of the first to appear on the market initially. Its advantages are considered relatively low cost, versatility, proven production technology, a large selection of color, texture solutions. The main scope of this type of product: household decoration, including bathrooms, halls, hallways, kitchens, utility rooms,

- 40x40 mm (45x45 mm) is a more massive version of the previous format, which has the same set of advantages, but already allows you to visually expand the interior,

- 60x60 mm - an option for finishing facade surfaces and facing office-shopping centers, airports, sports facilities, large halls. It is quite simple to install, has a balanced cost, more often comes in a wear-resistant design,

- 60x120 mm is an expensive, infrequently encountered format designed for non-standard work. For example, these are the demanded sizes of porcelain tiles for the facade or interior cladding of premium objects,

- 20x20 mm - finishing material intended for technical purposes (laboratories, warehouses, other premises with mobile equipment in use). The strength of such tiles is provided not only by the size of the sides, but also by the thickness (1.2 cm).

Facing floors with tiles 30x30 mm

The thickness of porcelain stoneware on the floor varies widely: from 3 to 40 mm. The following product groups are produced for this indicator:

- a thin plate from 3 mm can have dimensions up to 500x500 mm. Due to the low material consumption, the products have a low cost, but require careful surface preparation, extensive experience, and specialized tools for trimming. Because of their fragility, these sizes require careful transport. The main scope: rooms with medium loads, for example, kitchens, halls, small shops, as well as cases where it is undesirable to significantly raise the floor level,

- plate of usual thickness: 8.0-14 mm depending on size. This is the most common finishing material. It is used in the decoration of housing and public buildings with an average level of stress. The section of the plates is often 30x30 mm, 33x33 mm, 45x45 mm. These are the most suitable porcelain tile sizes for the facade. They also make products in the format of 600x600 mm.

- thick ceramic granite includes products from 14 mm in size. Sizes up to 40 mm are available on the market. Plates of this format are designed for buildings with high traffic, high loads, but are also used in living rooms. This allows you to create an interesting decorative effect, especially when using rectified ceramic granite laid by seamless technology. Thicker plates are suitable for outdoor installation, as they are not afraid of temperature fluctuations.

How to choose the right thickness and size

When choosing ultrafine ceramic granite, the following factors are taken into account:

- available in sizes up to 500 × 500 mm,

- the price of ultra-thin ceramic granite is lower than that of analogues,

- products are recommended for residential buildings with low loads,

- ultra-thin porcelain stoneware is not suitable for laying with your own hands, because it requires special skills, a professional tool.

On laying conditions, it is necessary to dwell in more detail, since customers often do not take this factor into account and focus only on cost when purchasing finishing materials. The small thickness of the granite in combination with the large dimensions imposes restrictions on the installation technology:

- gripping, carrying plates is carried out using vacuum suction cups,

- storage, marking, cutting is carried out on an even basis,

- the screed for laying should be perfectly flat,

- the alignment of the plates due to the adhesive layer is impossible,

- ultra-thin porcelain stoneware is suitable for laying on the previous finish without dismantling it. Old tiles serve as a kind of prepared base. Due to the small thickness, the new finishing layer will not greatly affect the height of the floors, and the installation option itself will reduce costs and repair time,

- thin large-sized porcelain tiles are cut on professional water-cooled tile cutters and diamond blades,

- porcelain tile cutting is carried out on a large foam slab,

- the thickness of the tile adhesive should be the same over the entire area. It is carefully leveled to remove voids that lead to breakage of the coating,

- do not use a rubber mallet to adjust ultra-thin products,

- with improper installation, the ultra-thin plate is difficult to remove for re-installation, since with a small thickness and strength of the element it is difficult to pick up its edge. The high adhesion of the supply glue to the ceramic granite also prevents this.

We recommend choosing ultra-thin large-scale porcelain tiles if professional tilers will be laying.

When choosing porcelain tiles of normal thickness, the following nuances are taken into account:

- plates have a thickness of 7-14 mm,

- the laying technology is simple, it can be done even by lay people,

- the material has a balanced level of operational parameters,

- produce mass products and large dimensions of porcelain stoneware tiles for flooring in non-standard projects,

- universal porcelain tiles used in residential, commercial, public, industrial premises,

- the thickness of frost-resistant porcelain stoneware is 12-14 mm,

- slab cutting is performed by standard tile cutter,

- in terms of format, ordinary ceramic granite complies with building codes, for example, SP 29.13330.2011 (Russian codes of practice are often late relative to commercial developments, therefore such an advantage is formal).

The choice of material by thickness

Tiles differ in design, performance, surface type, and other properties. When buying, it is recommended to consider the following features:

- technical porcelain tile has a thickness of 10 mm or more. It has a low cost. The material is used for finishing laboratories, warehouses, industrial facilities. The design of such tiles is the simplest. In the production, the emphasis is on ensuring high chemical resistance and anti-slip effect,

- glazed - made with an additional decorative layer, which provides high aesthetics of products. Application: repair of residential, public premises. They produce universal sizes of porcelain stoneware for wood, marble, abstract patterns, etc.,

- matte - undergoes processing of the front surface with coarse grinding wheels. Material is cheap. It has anti-slip properties. Differs in universality of application,

- polished - undergoes additional processing with abrasive materials. Therefore, the material looks spectacular. Due to the low surface roughness it is not used for flooring,

- structured - has a thickness of 10 mm, made by etching or applying additional components. This variety has an original relief that imitates leather, stone, other materials, but differs in low strength characteristics, high cost,

- semi-polished - takes an intermediate position between matte and polished,

- Satin - a material with high decorative properties, obtained by additional application of mineral salts on the front surface,

- Rectified - made by trimming the edges, so it fits on a seamless technology.

Ceramic granite of normal thickness is suitable for most projects. You can choose the material depending on the price, operating conditions, decorative properties.

Thick porcelain tile has the following features:

- plate thickness from 14 mm with large variability of sizes,

- the material is able to withstand increased loads,

- plates have a high cost,

- scope: premises and open areas,

- laying large porcelain tiles requires installation skills and considerable physical strength, but can be done on their own due to simple technology,

- more often thick porcelain tiles are laid without tile glue. Plates are placed on a layer of sand (with the addition of Portland cement), rammed with a vibrator,

- other schemes for professionally laying thick tiles are used, for example, on grass, gravel or supporting structures for raised floors. The thickness of porcelain stoneware for the street is from 20 mm.

Thick ceramic granite is a material for elite projects. You can install it yourself. But it’s more logical to order services from companies that are engaged in tile work.

How to choose porcelain tiles for the floor in thickness

For living quarters, porcelain stoneware 8–10 mm thick is suitable. For a bathroom and a restroom, choose 8 mm thick plates, because they have few heavy furniture and a low risk of falling solid heavy objects. For kitchens, corridors, hallways and living rooms, select 10 mm thick porcelain tiles. It will withstand the fall of the pan, the static pressure from the furniture on the legs.

For shops and places with high traffic, choose porcelain tiles 10-12 mm thick. For shopping centers, business centers and office buildings, 10 mm boards will be sufficient. They will withstand, even if several thousand people go through them a day and the pressure is not too heavy shelving with goods or office furniture. For construction stores, car dealerships and hypermarkets with a large number of goods on shelves, choose 12 mm thick granite.

For industrial and warehouse premises, select porcelain stoneware tiles for floors with a thickness of 10-14 mm. Such tiles are suitable for warehouses with high and heavy racks, car dealerships, carpentry shops, service stations.

Porcelain tile selection scale by thickness

Porcelain tile selection scale by thickness

The cost of porcelain stoneware per square meter depends on its thickness, therefore, we do not recommend choosing excessively thick slabs for rooms with a small load on the coating. Since the finer the porcelain stoneware, the lower its weight, you will save not only on the purchase of material, but also on its delivery.

Why the cost of porcelain stoneware depends on its thickness

The cost of porcelain tiles is directly dependent on the thickness of the plates. The thicker the porcelain tile, the more raw materials and coloring pigments are needed for its production.

Due to the increase in the volume of raw materials for the production of one plate, the duration of the process naturally increases. Mixing of raw materials lasts longer to ensure uniform distribution of pigment.

Along with this, the duration of the baking of the plates increases. The thicker the layer of raw materials, the longer the moisture evaporates from it and the processing temperature should be higher. So that the porcelain tile does not lose its strength, after baking, it should cool gradually. Thick plates cool longer and the process drags on.

The larger the thickness of the granite, the higher the risk of the appearance of plates of different calibers in one batch. During production, the volume of the mixture constantly changes, either up or down. Even the most modern computers are not able to measure the amount of raw materials to the nearest milligram. The greater the weight of the raw materials needed to produce one slab, the more difficult it is to predict what shrinkage it will result in.

How many centimeters will the floor rise after laying granite

The estimated thickness of the flooring you need to know in order to correctly calculate the height of the built-in furniture, the required amount of materials for wall decoration, the level of the height difference relative to the adjacent rooms.

Layout of a porcelain stoneware masonry layer on an infrared warm floor

Layout of a porcelain stoneware masonry layer on an infrared warm floor

If the floor height difference does not exceed 3 mm, granite tiles can be laid without prior surface leveling. So, plates with a thickness of 8 mm are laid on a layer of glue 4 mm, such a coating eats an average of 1-1.5 cm of the height of the room.

The greater the thickness of the plates, the larger a layer of glue is needed for their fastening. The required adhesive layer is approximately 40-60% of the thickness of the granite.

When the difference in floor heights of 3-7 mm is acceptable to level the floor due to the thickness of the adhesive layer. Such a coating, with a plate thickness of 8 mm, reduces the height of the room by about 2-2.5 centimeters.

If the floor level differences are more than 7 mm, it must first be screed and leveling. To do this, use self-leveling mixtures or pouring concrete screed on exposed beacons. Due to the screed, the floor level can rise by about 5 or more centimeters.

Technology of installation of porcelain tiles on the floor

The strength of floor stoneware tiles equally depends on their thickness and their proper installation. In order for the coating to not crack for the longest time and withstand all loads, observe the technology of its installation.

Technology of laying masonry with porcelain tiles (diagram)

Technology of laying masonry with porcelain tiles (diagram)

Lay porcelain tiles exclusively on a flat floor. The maximum allowable height difference for one plate is 3 mm. When the difference in floor heights of up to 10 mm is acceptable to level the surface by increasing the thickness of the layer of adhesive. If the height difference exceeds 10 mm, before laying the porcelain tiles, level the floor with a rough screed.

For fixing plates use only special glue. If you fix porcelain stoneware on a regular cement mortar, it may fall off or crack.

When laying, be sure to leave free space between the plates. So the glue hardens faster and holds the plates tighter. Seams between the plates prevent cracks from appearing if the plates become deformed over time or bend under the weight of furniture or equipment.

Make sure that no air pockets appear under the tiles during installation. In places of voids under porcelain stoneware, the risk of cracking increases.

See the full range of porcelain tiles for the floor in the catalog. To display only plates of a thickness suitable for you, use the Thickness filter.

To purchase the goods you like, contact the official distributor of Ural Granite in your area. To view the full list of distributors, click on the "Where to Buy" button next to the photos of any product.

No. 1. What is porcelain tile?

Porcelain tile is a very strong and durable type of facing coating, which can rightfully be considered a substitute for natural stone. The composition of porcelain stoneware includes such natural components as clay, mica, sand and feldspar, and a special additive in the form of granite chips gives this material special strength.

Porcelain is obtained by pressing and sintering. All components are mixed together in the required proportions, pressed at a pressure of 400-500 kg / cm², after which they are subjected to high-temperature annealing in an oven (1200-1300 ° С). Using this technology, it was possible to achieve the absence of pores in the finished material and its high strength.

At first, porcelain stoneware was used as a floor finish in industrial premises, with high loads, now technology has stepped far forward, which made it possible to use porcelain stoneware not only as flooring in residential premises, but also for wall and facade decoration. We will consider in more detail those types of porcelain stoneware that are used precisely as flooring.

No. 2. Benefits of Porcelain Tile

The main Advantages of porcelain stoneware:

- Environmental friendliness thanks to the use of natural ingredients.

- Low coefficient of water absorption. Due to the almost complete absence of pores, porcelain stoneware does not absorb water, which makes it frost-resistant. Also, the absence of pores allows you not to be afraid that the adhesive mixture appears on the surface of the tile and spoils it, as is sometimes the case with tiles.

- Chemical resistance, be it an alkali or other acid, which makes it possible to clean it by absolutely any means.

- Wear resistance and high bending strength. Porcelain tile is so durable that it has a very high bending strength per m², which makes it possible to lay it even on an uneven surface.

- Resistance to mechanical stress. The glossy surface of porcelain stoneware does not lose its luster and is scratch resistant for many years.

- Color consistency. Porcelain tile is absolutely not affected by ultraviolet radiation, which allows it to maintain the clarity of the pattern and color brightness even with prolonged exposure to the sun.

- Anti-slip coating. There is a matte, slightly rough version of porcelain stoneware that will remain non-slip even when wet.

- Thermal conductivity. This material does not allow cold and will retain heat well.

Number 3. Types of Porcelain Tile

The following types of porcelain stoneware are most suited as flooring:

- Technical porcelain tile. Ideal for flooring in the production room.

- Matt porcelain tile. This type of porcelain tile does not lend itself to any additional changes after going through a heat treatment cycle. This makes its surface a little rough and discreet. But it has increased hardness and anti-slip properties.

- Polished porcelain tile. A more capricious appearance than the previous one has a smooth, even surface, almost mirror-like, thanks to processing with abrasive substances. This treatment somewhat reduces its wear resistance. For a longer service life, it must be treated with special mastics that create an additional protective layer on its surface. Otherwise, during prolonged use, polished porcelain tiles smoothly turn into matte.

- Satin. This porcelain tile has an unobtrusive light shine, which is obtained by applying mineral salts to the surface before baking in the oven. This type of treatment does not affect the indicators of wear resistance.

- Structured the type of porcelain stoneware has a relief surface, it allows you to simulate the texture of wood (parquet stoneware), leather or various types of stone. Visually and to the touch practically does not differ from natural materials.

- Glazed porcelain is obtained by applying special glaze to the surface and subsequent firing. The glazed surface is much stronger than ordinary ceramic tiles, however, this type of porcelain tile is not recommended for use in rooms with high traffic and a high level of mechanical stress. Over time, he loses his outward appeal.

- Lappated porcelain stoneware has a mixed texture - half polished, half matte. This effect is achieved by removing a thin, uneven top layer using special polishing stones. This kind can be safely used for flooring in rooms with high traffic and high load.

- Double backfill. The top layer of the tile, approximately 3 mm, is made of components of the required colors, and the bottom layer of the main components. Thus, bright, colored tiles are obtained, the wear resistance of which is maintained at a high level.

Number 4. Porcelain classification

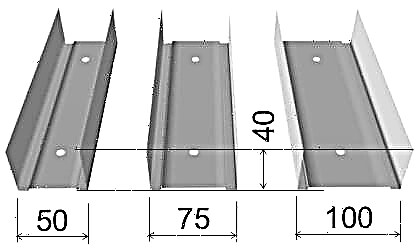

- The size. The most popular tile sizes for flooring are square tiles with dimensions of 300 × 300 mm, 450 × 450 mm and 600 × 600 mm. If you have some kind of design and unusual project in mind, and the floor will be the center of your interior, then you also have at your disposal tiles of the smallest size - 50 × 50 mm, and non-standard sizes - 200 × 200 mm, 150 × 300 mm, 300 × 450 mm, 300 × 600 mm, 400 × 400 mm. If you still haven’t found the right size for you, you can get it using waterjetcutting.

- Caliber - this is the value of the allowable discrepancy in the size of the tiles, component 3-5 mm. During the heat treatment, the edges of the tiles are slightly deformed, so they can differ from each other in order to avoid a large difference in size, the tiles go through the process rectification, that is, trimming the edges on special equipment. Such tiles of porcelain during subsequent installation will be coincideperfect.

- Thickness. The maximum thickness of porcelain stoneware is 30 mm, the minimum is 3 mm. At rightstyling flooring with a thickness of 3 mm, its strength and wear resistance is in no way inferior to a coating with a thickness of 30 mm, so it makes no sense to give preference to the thickest, and therefore more expensive porcelain stoneware. For example, recommended it is for flooring tile thickness 8.5 mmwithstands a load of 200 kg / cm 2.

Abrasion class. Abrasion (wear resistance) - home technical characteristic porcelain stoneware. Depending on the degree of stress and mechanical stress, they are distinguished 5 major grades abrasion resistance:

- PEI I, PEI II - for rooms with low passability in soft shoes (bathroom, toilet),

- PEI III - for residential premises with an average level of cross-country ability, without access from the street or from the yard (balcony, kitchen, hallway),

- PEI IV - for public areas with a high level of patency,

- PEIV - for rooms with any level of patency and mechanical impact.

For example, for flooring in the whole apartment, class III abrasion is quite enough, and for bath and toilet, I or II class can also be used. If your task is to choose porcelain stoneware for a private house, then select class IV in the corridor, and for the porch, give preference to class V, which, moreover, is frost-resistant. In the remaining rooms, III class will also be sufficient.

No. 5. Is porcelain tile and tile the same?

Many people mistakenly believe that this is really the same type of flooring, they just decided to reduce the name and raise the cost ... But this is far from the case. Differences really have what significant:

- Porcelain undergoes heat treatment at a significantly higher temperaturesthan tile, which explains it higher strength and wear resistance.

- Due to high temperatures, the components of porcelain tiles literally melt during processing, which is completely eliminates the appearance of micropores. This prevents moisture from entering the internal structure, therefore porcelain stoneware is able to withstand highsubzero temperatures and do not crack at the same time. The tile has a porous structure and does not withstand large temperature differences.

- Porcelain stoneware is easy to clean - due to the absence of micropores, the surface is less polluted. Enough wet cleaning to maintain its beautiful appearance.

- Porcelain stoneware absolutely steadyto any chemicals. This facilitates the cleaning process. Tile does not tolerate aggressive substances and can lose its luster from exposure to it, for example, alkalis.

- On the surface of porcelain stoneware, even after a long time, cracks and chips do not form. Despite the fact that on the tile you can observe microcracks on the surface after a couple of years of operation.

- Porcelain tile, due staminato the impact ultraviolet light, even after 50 years, it will not lose its color and clarity of the picture, which can not be said about tiles, which eventually fade.

- On the surface of porcelain stoneware practically no stains. Have you noticed that when laying tile, the adhesive mixture sometimes appears on the surface and has to be changed, since this is an irreversible process? With porcelain, this will never happen thanks to his monolithicstructure. Even if a coloring substance is poured onto the surface of porcelain stoneware, it can easily be removed without a trace.

- Porcelain tile has a large indicator bending strength, which allows you to lay it not even on an uneven surface. The tile breaks at the slightest distortion.

- The best porcelain tiles have absolutely smooth and clear edgesthat allows you to perform seamless styling.

No. 6. Application area

Due to the variety of colors and textures and their constancy, resistance to mechanical damage and chemicals, frost and bending, porcelain stoneware is used for wall and floor cladding as inside premises so and outside. Due to its high rates of hardness and abrasion, it is an ideal type of coating for industrial and public buildings. It is also used for decorating halls, swimming pools, floors in cafes and even at train stations. After all, this material is really eternal, and the possibility of producing various sizes makes it practically universal. Whatever room comes to your mind, you can always pick up the necessary type of porcelain tile. Porcelain tiles even replaced parquet! And visually and to the touch does not differ at all from a natural tree.

Number 7. Disadvantages of Porcelain Tile

Despite a number of significant advantages, as with any material, limitations porcelain stoneware also has:

- Porcelain Tiles able to prevent the passage of cold and retain heat, but, by itself, this material cold, in fact, like tile. The solution is to use underfloor heating.

- All types of porcelain stoneware, except for technical, matte and structured ones, when wet, will slippery.

- Of course, it’s worth noting highcost porcelain stoneware compared to tile. But in this case can argue, because it’s better to spend money once and get coverage with a guarantee of 50 years or morethan constantly changing cracked or burnt tiles. Moreover, now there are a lot of types of porcelain tiles from different manufacturers with different pricing policies. The highest price for Italian porcelain tiles, but there is also Belarusian, Turkish, Greek and Baltic, which allows you to choose the material with the best price-quality ratio.

Number 8. What should I look for when buying?

- Before buying, you must already know which the size Do you want to tiles. So you can easily navigate their quantityby dividing the desired coverage area by the area of one tile.

- Please note that all tiles match color and shade. All tiles must be from the same batch, otherwise the difference in color will be very noticeable after installation!

- Caliber all tiles should also be the same - This will ensure a beautiful, even styling without any visible differences in size.

- Required check weight! Recommended tiles for flooring, 8-8.5 mm thick, have a weight of at least 18.5 kg. Feel free to clarify this point, otherwise you risk buying a fake!

- back side tiles can also say a lot. It should have shallow, small squares with sides maximum 2 × 2 cm. The larger and deeper these technical notches will be, the lower the quality of the material.

- Do not forget about stock, which should be 10% of the total number of tiles with a diagonal laying method and 5% with other methods.

- On the packaging of porcelain tiles for flooring will be shown black footIf this sign is repeated, it means a higher class of wear resistance. If you will see snowflake - it is frost-resistant porcelain tile.

No. 9. Features of laying granite

If you decide to refuse the expensive services of professionals, and decide perform styling porcelain tile independently, you should very carefully approach this issue, because the durability of the coating will depend on the correct installation.

Porcelain tile, as a very durable material, is very difficult to cut so that you do not have difficulties and surprises during the laying process, prepare everything at once necessarytools:

- You will definitely need tile cutter or Bulgarian

- Necessarily building level

- Flat edge spatula - for applying an adhesive mixture and a spatula with a serrated edge - for removing excess solution

- Construction bucket or other convenient for work capacityfor adhesive kneading mixtures

- Drill and special construction mixer to facilitate the kneading process

- Capacity for water

- Rubber hammer

- Plastic crossesthat adjust the width of the seam are chosen to your taste

Since porcelain stoneware is very heavy, it is necessary to choose a mixture that will withstand heavy loads. Better to choose plastic adhesive mixture with high indicators of “tenacity”, in addition, it prevents tile lagging if your house has not yet fully settled down and “walks” with changes in temperature or foundation settling. When the adhesive mixture is selected, go to the next step.

Surface preparation

Although porcelain stoneware and provides for differences of up to 15 mm, it is better to level the surface beforehand, by pouring concrete, previously waterproofing, then carefully primer. If porcelain stoneware is laid on a warm floor, the sequence will be as follows - waterproofing the premises, laying a warm floor, pouring concrete (screed), soil impregnation, laying granite. By the way stylingon old wooden floors not allowed. After preparing the surface, you can proceed to the mixture. Stir the adhesive mixture according to the instructions on the packaging. If you are laying tiles for the first time, do not knead the whole mixture at once, suddenly you will have difficulties in the process, and the mixture retains its adhesive properties for not so long. It’s better to start with a small amount, literally a couple of tiles and try to lay them, thereby checking their capabilities.

Stoning knramogranita

The sequence of actions is as follows:

- Mark the place for the first tile

- Apply a small amount of the mixture to the base with a smooth spatula and evenly distribute

- With a comb spatula, “comb” a place under the future tile; remove excess mixture

- Lean the tile firmly on the marked area

- Tap with a rubber mallet and remove excess mortar around the tile

- Put the next tile taking into account the thickness of the plastic crosses

If you want, using a thicker layer of adhesive mixture, to compensate for surface irregularities, then it is better to additionally apply glue to the tile itself. "Comb" the mixture on the base and on the tile must be perpendicular to each other. If you are facing the porch, give your preference seamless method. If, nevertheless, it is not possible to replace wooden floors with a concrete screed, then a layer of moisture-proof plywood must be laid on top of the old flooring. The adhesive mixture in this case must be elastic.

When laying porcelain tiles on the floor, you are unlikely to avoid the need to cut, for example, holes for pipes near radiators. It is also very rare that all tiles lie whole across the entire width or length of the room. A grinder or tile cutter will help you cut off the excess. And for figured cutting, it is better to use a jigsaw with diamond wire. Do not forget that trimmed tiles are better laid in the place where the furniture will stand and they will not be visible.

Superthin porcelain tile

Thin 3mm Porcelain Tiles

The newest material, for many still unknown. The thickness of ultrathin plates up to 4 mm, linear dimensions within 500 × 500 mm. Advantages - the most affordable price. Disadvantages - low strength indicators, can only be used in residential premises with low loads on floor coverings. Such a small thickness and large dimensions create certain difficulties and restrictions on the laying time.

The first and most important limitation is that beginners should not even try to lay ultra-thin porcelain tiles. To work with them, special tools and extensive practical experience are required. Plates can be grabbed with vacuum suction cups, you need to carefully transfer and lay on a carefully prepared base.

Using suction cups to lay the slab

Ultra-thin porcelain tiles are placed only on perfectly flat surfaces. Aligning them by changing the thickness of the glue will not succeed. Most often, such material is used during the repair work of floors with ceramic coatings. A very small thickness allows them to be laid immediately on old coatings, the height of the premises decreases by only a few millimeters, which is completely invisible. In addition, it is possible to significantly speed up the repair, there is no need to waste time removing old ceramic tiles and leveling the base. This is a very time-consuming task, the time of removal of the old coating and surface preparation is several times longer than the time of laying new plates.

Laying porcelain tiles on the floor

For cutting ultrafine porcelain tiles, experience is needed, with slight deviations from the recommended technologies, they will crack. Plates are cut with a fully serviceable tool, the slightest vibration of the disk of the circular grinding machine is prohibited. If possible, it is recommended for these purposes to use professional cutting equipment with diamond blades and water cooling. It is necessary to cut on an even plate of polystyrene foam, its dimensions must exceed the parameters of the cut tile.

How to cut porcelain tiles

The glue is applied only with a comb, the thickness of the material should be the same over the entire area. If with a thickness of plates within 7–12 mm a rubber mallet can be used for fitting, then it is impossible to work with superthin ones with it. In addition, any air pockets between the base and the slab cause a violation of the integrity of the coating.

Glue is evenly distributed on the floor in place of the tile

Due to the large size, it is difficult to control the spatial position of the plates. Looking for long slats and a great fit experience. Incorrectly laid ultra-thin slabs are almost impossible to remove to correct errors. The glue has high adhesion, and the low strength of the plate does not allow it to be peeled off on one side for removal. Laying should be done the first time.

Laying porcelain tiles on the floor - top view

The novelty of the material and the difficulties with laying became the reason for the low popularity of such plates among developers. The material is used quite rarely and only by specialized construction companies having professional craftsmen and a complete set of necessary tools and devices. They don’t “love” such thin slabs and distributors - there is too much risk of material damage during loading / unloading in warehouse and retail premises.

Porcelain tile with ordinary thickness

The most common category of porcelain tiles, the thickness ranges from 7-14 mm. According to physical indicators and operational characteristics, they meet the requirements of developers. Plates of universal use, are used as finishing coatings for floors of premises for various purposes, from residential, to state, commercial, office and industrial buildings. The dimensions of the plates are from 50 × 50 mm to 600 × 600 mm, they are perfectly processed with simple tools, the laying technology is ordinary.

Formats and Thickness

The existing state regulatory documents of SP 29.13330.2011 establish the minimum strength of plates within 200 kg / cm2, specific values are tied to the intensity of loads on the flooring. A rather large thickness makes it possible to expand the range of materials, tiles with standard thickness can be:

- technical. The cheapest, used for the construction of floors in industrial and warehouse premises. The thickness is not less than 10 mm, the front surface after annealing is not further processed. They do not react with aggressive chemical compounds, due to the rough surface, the sliding effect is eliminated - the work of loading and unloading mechanisms is facilitated, the risks of personnel falls are minimized,

Tiles with ordinary thickness are used for finishing floors inside and outside buildings, it can be laid in the subway and supermarkets, in residential apartments and prestigious offices, in concert and sports halls, airports, railway stations, etc. According to the vast majority of professional builders, the use of ceramic granite slabs of standard thickness is a justified and cost-effective solution.

Thick Porcelain Tiles

Thick porcelain stoneware 12 mm compared to 8 mm

This category includes plates with a thickness of more than 20 mm, various linear sizes. Withstands high loads, can be operated both indoors and outdoors. In our country it is used quite rarely due to the high cost. The plates are heavy and require considerable physical strength during installation. The technology for laying works differs from tiles with ordinary thickness. The main difference is that thick porcelain tiles in most cases are laid without the use of glue.

Porcelain tile 20 mm

The site is pre-leveled and filled up with a layer of sand up to ten centimeters thick. Sand is carefully rammed with special vibratory machines, after tamping the surface is re-checked, revealed deviations are poured.

Practical advice. To increase the strength of the base, sand should be sprinkled with cement at the rate of one bag per 10 m2. After laying the slabs, the cement will bind to the sand, which will significantly increase the strength indicators of the base.

With the help of the rope, marking is done, the rope must always be on the working platform, with its help the correct position of the plates is controlled. Thick porcelain tiles are laid in turn, a little sand is poured under each plate, large rubber hammers or heavier devices are used to adjust the position. It is necessary to cut plates on special equipment, it is very difficult to perform such work with an ordinary grinder. In addition, it then takes a lot of time to smooth out an uneven cut.

The horizontal position of the plates is controlled by a long level or even rails. After completion of work, the surface is sprinkled with dry sand and cement, sprinkling with brooms is swept away to the sides.

At the same time, this mixture closes the joints between the plates. The seedling phase is the installation of thick porcelain stoneware slabs - abundant wetting of surfaces with water. This technology allows you to turn dry sand and cement compositions into a durable cement-sand mortar, the reliability of the installation of slabs is significantly increased. It is not recommended to load the slabs as much as possible during the first two weeks after installation, this time is required for the hardening of cement mixtures.

Thick plates are mostly used during the construction of car parks, areas in front of supermarkets and offices, for the arrangement of certain zones of city squares and parks.

20 mm thick reinforced thick porcelain stoneware - styling

Features of porcelain stoneware

Porcelain tile is a unique type of facing artificial stone, which is obtained by pressing certain components and then firing this mixture at a temperature of about 1300 degrees Celsius.

They are manufactured with the following modifications:

- giving surfaces the appearance similar to natural materials: wood, stone, metal,

- drawing on the surface of a variety of textures, patterns,

- the use of various coloring substances,

- giving unique physical features: a different indicator of the roughness of the tiles, a change in thickness, the original molding (both linear and complex figures).

Porcelain Tile Thickness

When the owner makes a choice between different types of porcelain tiles, he must carefully study all the features of each of the proposed products. As already mentioned above, the article will discuss what thickness of porcelain stoneware for the floor is optimal and how to lay each of the existing types of this material (see also: "Laying porcelain stoneware on the floor with your own hands: the device for flooring with examples").

A pattern is observed: the greater the thickness indicator, the stronger the porcelain tile. Accordingly, a product with an increase in thickness will be easier to restrain physical stress and shock, which will allow you to adapt the tiles for use in various rooms. However, there are certain factors that can adjust the process of laying and operating tiles.

According to the standard, the thickness of porcelain tiles is from 0.7 to 1.2 centimeters. Certain rooms require less thickness or vice versa allow the use of more durable and thicker products. Accordingly, the cost of lining will vary in proportion to how the thickness of the floor tiles changes. So, we will consider the main indicators of the thickness of porcelain tiles and the features of their installation.

Standard thickness porcelain tiles

As already mentioned, a thickness of 0.7-1.2 centimeters is inherent in standard porcelain tiles. This type is the most popular among builders, as Its specifications are optimal. With the help of such plates, floors are covered both in residential buildings and in facilities where there is a constant flow of people, and, accordingly, a large load on the coating. The linear dimensions of the plates can vary in the range from 5x5 to 60x60 centimeters.

The use of this facing material is described by state regulatory documents that contain information about the allowable load on the coating.

The standard thickness of porcelain stoneware for the floor allows you to create additional varieties of tiles:

- technical - have the lowest cost and are used to create flooring in industrial plants and in warehouses. The tile received this name due to the lack of additional surface treatment. The advantage of the material is that it does not respond to aggressive environments, and a rough surface without processing eliminates the effect of sliding, increasing the safety of the work process,

- glazed - this is the most expensive type of material, which has in its composition an additional layer of a substance that allows after firing to give the material a different surface color. This type is used most often in residential buildings or elite institutions, where the aesthetic beauty of the flooring is very important,

- matte - after the firing stage, the front surface of the granite tiles is ground with a coarse-grained circle. As a result, the tile does not slip, but looks very presentable, which allows you to take a pre-sale photo of floors in the house or show them to guests. The cost of this material is low,

- polished - Outwardly, they are the height of perfection, and in cost they exceed all other varieties. The disadvantage of a polished surface is that it cannot be used in open areas (balconies, terraces, verandas, etc.), since the effect of natural precipitation causes destructive processes on the front side,

- structured - their thickness should not be less than 1 centimeter, since a lower value will affect the strength characteristics of the product. Such requirements arise due to the relief of structured tiles. In places where there are recesses, its thickness will be critical, and increased load will cause deformation. The advantage of this type is that the front surface can be an imitation of parquet, fabric, leather, etc. In special cases, it is treated by etching or by applying a layer of gold leaf.

The technical characteristics of this variety of porcelain tiles allow you to use them anywhere. Experts believe that such material is the most reliable, efficient and cost-effective.

Thickness Tips

After reading this article and familiarizing yourself with all the operating conditions of each of the varieties of porcelain stoneware, do not immediately rush to the market for thick porcelain stoneware. It must be understood that airy voids even under this form will cause a split in the structure with little physical exertion.Therefore, the main task of the buyer is to take care both of choosing tiles of suitable thickness and of finding a specialist who will lay.

You can check the quality of tile laying, both with self-assembly and in the event that work is carried out by hired workers. It is enough to tap the surface to understand where voids are hidden under it, if any. Such places will resonate with a loud sound when you hit a tile.

At the time of purchase, you need to check the materials to understand how high-quality they are. Linear dimensions can be checked with measuring instruments. To find out how smooth the surface is, it’s enough to just lay down one tile from two packages between each other and check the absence of gaps between them, as well as the perfect matching of the perimeters will tell about the high quality of the products.

Total

From all of the above, it can be understood that when choosing ceramic granite tiles, it is necessary first of all to rely on the technical characteristics of the product. Cost is not the main indicator, since the owner who wants to save will make a terrible mistake. The insufficient strength of the tiles will lead to their destruction, and the excessive mass of thick porcelain stoneware can adversely affect the foundation, and much more money will have to be allocated for the purchase of material.

Accordingly, the most effective solution will be to seek help from a specialist who will make the necessary measurements, select the type of porcelain tiles and perform the installation in the shortest possible time.

Practical tips for choosing the thickness of porcelain stoneware

Do not immediately buy thick porcelain tiles, the strength of the floor depends not only on this indicator, but also on compliance with the masonry technology. If the master does not use a special comb to apply an even and uniform layer of glue, but “sculpts” it with a staple only in several places of the tile, then even thick material in the places of admission can crack from relatively small forces.

Work with glue for porcelain tile

It is recommended to check the integrity of the performers. There are two ways to do this: to observe their work or to check the already installed tiles. The first option is not always possible, but it is never too late to check the floor. The tile floor needs to be tapped, the sound over the entire surface of the tiles should be the same and deaf. If there are places with a loud knock, the work was done by an unscrupulous or unskilled performer, between the tile and the base there are large air chambers not filled with glue.

Layout of porcelain stoneware laying

When buying material, be sure to pay attention to linear dimensions. The thicker the tile, the more complicated the annealing technology, the higher the risks of getting a defect. Take two tiles from different packages and attach them to each other with their face planes. Reel or gaps between them are strictly unacceptable, the edges should be smooth and perfectly match. Porcelain tiles are much more difficult to align than ordinary ceramic tiles, because of this, the requirements for it in linearity and flatness are more stringent.

The thickness of the tile has a significant impact on the price for all other identical indicators. Practitioners know that properly laid 7 mm thick porcelain tiles can withstand the same forces as 12 mm thick tiles, but made with scrap. And at a price these materials differ significantly. Conclusion - a professional master tiler can save substantial finances, while the strength of the flooring will meet the required parameters.