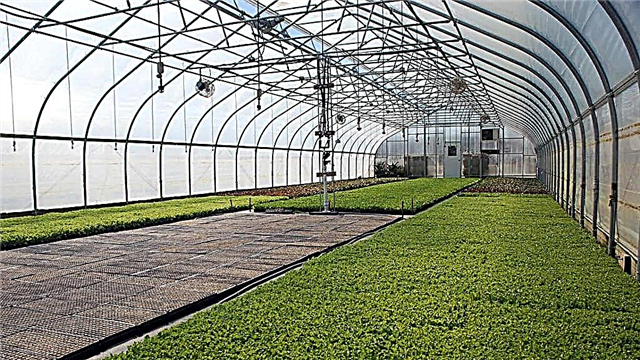

Greenhouses made of polycarbonate are very fond of summer residents, as they allow you to grow a plant in any climatic conditions and get a good harvest.

They are used to obtain seedlings, early herbs, first radishes, heat-loving vegetables and berries.

Types of polycarbonate greenhouses

By location, all the greenhouses can be divided into:

- In-depth - this is a trench along the perimeter of which they put a strapping of logs, brick or metal, and an external frame is attached. It is best to use wood, as it has good thermal conductivity. In such hotbeds, a thick layer of earth is used as thermal insulation, as a result of which heat is perfectly preserved and there is no need for additional heating.

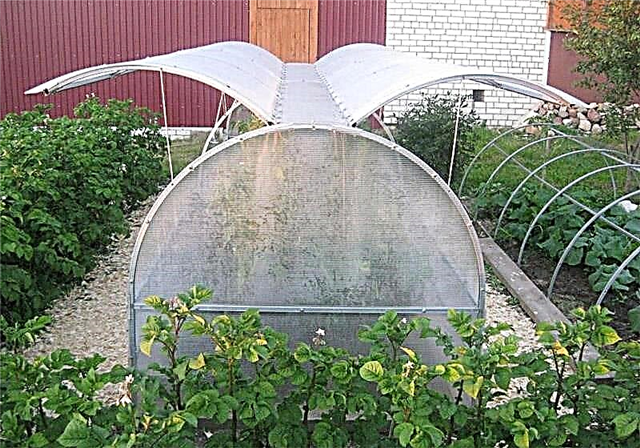

- Elevated ones have the advantage that they can be rearranged from place to place. But they are colder than deepened. Such greenhouses in the form of opening the roof are of the following types: “butterfly”, “snail”, “Belgian”.

By design, greenhouses are:

- Sheds have a one-sided roof. They can be installed under the wall of the house, using the wall of the building as one side.

- Gable with a roof on 2 sides. This is the classic version that most greenhouses have. Since it is more convenient to install transoms for ventilation on 2 opposite sides of the roof. You can choose any greenhouse on the site - agroparnik.com.ua.

Advantages of Polycarbonate Greenhouses

The following advantages are in favor of polycarbonate greenhouses:

- strength and durability

- keep heat well

- lightness and flexibility. Such a greenhouse can easily be moved to another place, and polycarbonate is able to take a different shape.

- transmits light, but not ultraviolet.

DIY polycarbonate greenhouse

It is easy to work with polycarbonate, so you can build a greenhouse using this material yourself. On the Internet there are many ready-made drawings of different models of greenhouses.

First of all, you need to determine the size of the greenhouse. For an in-depth greenhouse, a width of up to 1.5 meters is acceptable. Next, you need to decide with the model: aboveground or in-depth. And finally, choose whether the roof will be: single-pitched or gable.

To make a buried greenhouse, you first need to dig a hole to the size of the greenhouse, fill it with manure, and pour the land on top of it with a bed. Next, we install around the perimeter a log harness, on which the frame will be attached.

The most difficult is the manufacture of the frame, it is made of wood, galvanized profile or metal-plastic water pipes. The next step is the installation of polycarbonate sheets on the frame. In this case, you must try to avoid gaps, the joints are tightly connected.

A feature of the polycarbonate greenhouse is that it can be used year-round, they do not need to be cleaned for the winter. If a steel profile pipe was used at the base of the frame, it can withstand wind and snow loads.

Material and frame design

The classical greenhouse is an agricultural construction designed to provide reliable protection of plants from adverse environmental factors. Its basis is a supporting spatial frame of a certain shape. In the construction of greenhouses are guided by the requirements of GOST R 54257-2010, SNiP 2.10.04-85 and SP 107.13330201. These regulations determine the technical conditions and requirements for the design of greenhouses.

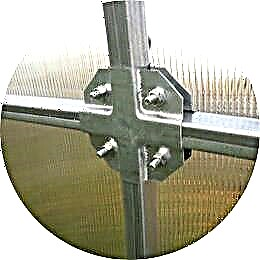

For the manufacture of the supporting frame of this structure, a galvanized thin-walled profile or a steel pipe of rectangular or square section is used. Each of the above materials has its own advantages and features that must be considered when choosing it as the basis for the greenhouse.

Galvanized Bent Profile

Galvanized steel profile is light weight and reasonable price. Moreover, its mechanical strength is clearly insufficient, which is offset by the use of a larger number of elements. The connections between the individual parts of the frame need additional reinforcement. Often such a frame consists of many joints, and the thickness of the metal is only 0.5 - 0.8 mm, which is clearly not enough to withstand peak wind and snow loads.

Galvanized Bent Profile

Galvanized steel frame

Steel profile rectangular or square

The supporting frame, welded from a steel pipe of rectangular cross section, is characterized by durability, high resistance to constant and variable mechanical loads. Its main disadvantage is the tendency to corrosion and the need to protect parts from rust. The frame of the greenhouse is quite complicated to manufacture, which determines the high cost. The arcs of such greenhouses consist of only a few elements, and can even be whole.

Square steel profile

Steel profile greenhouse frame

The choice of material for the construction of the frame is based on the requirements and capabilities of the customer. If you are going to purchase a finished greenhouse, then most likely you will be offered a frame on a thin-walled profile, less often there may be a frame from a profile of rectangular or square section. The best option for strength is a frame made of rectangular or square profiles. The frame from a thin-walled profile will be less durable, but much cheaper and there is a greater chance of running into low-quality manufacturers, which, in order to save money, make the frame not rigid enough.

However, this does not mean that you should abandon such a frame. Just before purchasing such a greenhouse, you need to make sure that it is really durable, and the metal thickness is at least 1.2 mm. As a rule, each seller has samples of frames, you just need not to be lazy to come and carefully consider the options available. If the seller in every possible way hides and does not show samples of frames, there is a high probability that you will be sold a low-quality product.

When choosing a frame, also pay attention to the following points:

- How many elements are made up of arcs, ideally so that they are seamless.

- It is best if the frame profile has a rectangular section of 20 × 40 mm, this is especially true for the base of the greenhouse, because if it is made from a profile with a section of 20 × 20, this may not be enough.

- The thickness of the metal should be at least 1.2 mm., Otherwise there is a big risk that the greenhouse will not stand idle for a long time.

Polycarbonate Type

Today on the market there are two types of polycarbonate - cellular and monolithic. Among these materials, cellular polycarbonate has the best characteristics for use as a roofing material in a greenhouse.

Cellular polycarbonate is a sheet material from the group of thermoplastics, consisting of two or more layers with longitudinal internal jumpers. This plate structure provides excellent technical characteristics and operational properties of the material.

The most significant of them during the construction of the greenhouse are the following:

Low specific gravity High thermal resistance High light transmission High flexibility Resistance to climatic conditions High mechanical strength Technical characteristics that are significant for solving the question of choosing cellular polycarbonate for the construction of a greenhouse are presented in the table: High-quality cellular polycarbonate has excellent selective transmission properties. It almost completely absorbs ultraviolet radiation with a wavelength of 400 nm or less, the most dangerous for plants and transmits visible and infrared rays to the maximum. This helps to create a greenhouse effect. To protect cellular polycarbonate from the destructive effect of ultraviolet radiation on its outer surface, a layer of light stabilizing substance is applied by coextrusion. You can find out about the presence of such a protective coating by the corresponding inscriptions on the protective film glued to the polycarbonate sheet. You need to be careful here. If there are no special marks on the protective film, this means that they are designed for indoor use. An attempt to use such materials for the manufacture of a greenhouse will lead to premature failure of the coating. One of the most important properties of polycarbonate is the ability to maintain its technical characteristics throughout the life of the panels. Some manufacturers claim that UV protection is in the bulk of the material. In fact, it is not enough and it is intended only to prevent the destruction of the material during storage. When choosing cellular polycarbonate for the construction of greenhouses, the thickness of the sheet is crucial. The specified parameter directly determines such properties of the panels as the light transmittance, the level of thermal conductivity and the ability to withstand mechanical loads. For the construction of greenhouses, sheets are usually used with a thickness of 4 to 10 mm, most suitable for the main parameters. The thickness of the sheet is determined based on the structural design of the frame, an increase in this parameter increases the resistance to wind and snow loads. In some cases, different panels can be used on the same structure. For flat and arched roofs, sheets of greater thickness are used, and vertical walls are made of thinner panels. The most optimal is the use of cellular polycarbonate with a thickness of 4 - 6 mm. It is necessary to make sure that the panel thickness declared by the manufacturer is actual. To do this, the panel can be measured with a caliper. If the declared and actual thickness of the polycarbonate sheet does not match, the use of such material should be discarded. In no case do not agree to buy polycarbonate with a thickness of 3.5 - 3.7 mm. At the same time, sellers may say that this material has a higher density, so it can be used instead of sheets with a thickness of 4 mm. But most likely it is low quality polycarbonate, which has an extremely low service life. If polycarbonate easily bends from the effects of fingers and does not have a designation on which side the light-stabilizing layer is located, then this is a cheap material that has a service life of no more than 2 years. In the process of choosing cellular polycarbonate for the construction of a greenhouse, special attention should be paid to the following points: Arched greenhouse is a structure with a semicircular overlap. The spatial frame consists of arcs located at a certain distance from each other with transverse connecting elements. This type of greenhouse is most prevalent among the population. The structure can be quite easily increased or decreased in length. This is done by adding or removing individual sections. Such a structure has a rather modest size and is more likely a greenhouse, its main convenience is the possibility of easy access to the garden and the organization of ventilation of the internal space if necessary. Consists of two curved surfaces connecting line, which forms an acute-angled ridge. Such a device prevents the formation of snow on slopes. An additional stiffener ultimately helps to increase the strength of the structure. The simplest structure, which uses the building envelope of residential or office buildings in personal plots as a supporting structure. During construction, a sufficiently large slope angle to the vertical is specified, which prevents the formation of a stable snow cover on the surface. The facility is located on the sunny side of the building to maximize the use of natural light. The gable classic greenhouse before the appearance of plastic polycarbonate was the only possible form. In appearance, it resembles an ordinary house with vertical walls and a flat roof. The simplicity of the design makes it possible to manufacture it without the use of equipment for arching arches for the arch frame. This design can be built from any materials, including wood. When choosing the form of a greenhouse, the owner is guided by several factors, primarily its purpose and its own financial capabilities. For growing seedlings, a small wall structure or a greenhouse with lifting walls will be enough. Vegetable production will require solid arched or gable greenhouses with corresponding costs. When determining the size of a greenhouse, its purpose and planned production volumes are primarily taken. Design work, even in the most simplified version, allows with sufficient accuracy to calculate the required amount of materials. General rules for the implementation of such events are as follows:

Material thickness 4,0 6,0 8,0 10,0 The specific weight of the sheet, kg / m2 0,8 1,3 1,5 1,7 Sheet dimensions, length × width, m 6(12) ×2,10 Thermal conductivity, W / m2 ° С 3,9 3,7 3,4 3,2 Light transmission coefficient,% 83 82 82 80 Maximum and minimum temperature, ° C From - 110 ° С to + 145 ° С Service life, years 10 15 20 Minimum allowable bending radius, m 0,7 1,05 1,5 1,75 The presence of a light stabilizing layer

Cellular Polycarbonate Thickness

Arched greenhouse

Arched type greenhouse with lifting sides (butterfly greenhouse)

Greenhouse with a drip arch shape

Photo: jrmk.netShed or wall greenhouses

Gable Greenhouse

Photo: www.as-superstore.atDimensions of the greenhouse and individual elements

Fixing the structure to the foundation

The vast majority of greenhouses have a relatively light construction and significant windage, and can be turned over by the wind. Polycarbonate greenhouses must be carefully fixed to the base, which can take the form of a strip foundation with a brick or stone base. The device of such a supporting structure requires significant investment and is used only for large enough stationary greenhouses.

The mounting of the supporting frame to the foundation is carried out through the use of embedded elements. Steel pipe structures are usually welded to special metal parts embedded in the base. Galvanized steel frames are fastened to masonry using dowel nails or anchor bolts. The latter installation method is more reliable.

The question of choosing a polycarbonate greenhouse comes down mainly to determining its size and shape based on its purpose and the capabilities of the owner. High-quality construction must be correctly installed on the site, which will ensure its long-term operation.

Greenhouse selection criteria

Any greenhouse is a simple structure, which consists of two main elements - a frame and an awning. In most cases, they are sold separately, but there are options for finished designs in which the manufacturer provides for virtually every little thing.

In any case, the selection of the greenhouse is carried out according to two main parameters:

First of all, you need to determine the shape of the greenhouse. The market offers many models from domestic and foreign manufacturers.

The following types of structures are distinguished:

- with vertical walls,

- with inclined walls,

- arched

- single slope

- gable

- with a roof attic type.

The selection is wide. You can find exactly the option that suits you in every way. One of the most important selection criteria is the convenience of the greenhouse. And here a summer resident is offered a lot of opportunities to minimize labor costs for growing crops. The “smart” greenhouse will fulfill most of the tasks of ventilation, watering, heating. You can choose a model with the set of functions that is necessary for a specific climate and site.

Polycarbonate Benefits

Few people know how to choose a polycarbonate greenhouse. Tips and reviews of gardeners will help us in this matter. Today, such material for creating greenhouse structures as polycarbonate is gaining more and more popularity. Probably everyone knows that a good greenhouse should be reliable, durable, perfectly save heat and at the same time let in sunlight.

With proper handling, polycarbonate can last for many years. The strength of the greenhouse frame ensures that the structure will delight you with its amazing fruits for decades. The most important thing here is that polycarbonate perfectly retains heat. It performs this function due to its honeycomb structure.

Air is placed in the cells, which allows the material to inhibit the air exchange between the greenhouse and the environment. Polycarbonate is also treated with a special varnish, thanks to which ultraviolet can not get into the room. Its plasticity and flexibility allows for easy installation of the greenhouse.

The advantages of polycarbonate are as follows:

- Transmits light. Allows sunlight to penetrate the building to the maximum.

- Durability. Raw materials can serve faithfully for more than 20 years.

- Sustainability. Varies depending on the density of the material. But at the same time, each version is resistant to mechanical damage. Also, raw materials perfectly protect against moisture penetration.

- Variability. The cost of a greenhouse is determined by the properties of the raw materials from which it is produced.

You can choose the right greenhouse when the selection criteria are known. An impeccable greenhouse from a bad one is distinguished by the density of raw materials, the ability to transmit light, and water resistance. Today, an impressive range of polycarbonate greenhouses is presented on the market, which vary in price category and characteristics.

Which greenhouse is better?

Many people ask, "What are the best polycarbonate greenhouses?" A clear answer to this question does not exist, since they can be of various shapes and sizes, they are made of various materials. It is important to know which design to choose. It can be galvanized steel cold rolled. It may take the form of a carrier pipe or profile.

The best greenhouse, as a solid housing, should have exemplary walls, a roof and a base, that is, a coating, frame, foundation. The most straightforward variation of the greenhouse is considered unheated. It is used for growing early crops, so that before the onset of cold weather to harvest.

A variety of versions of greenhouses allows you to choose an affordable and suitable option. The most common types combine an affordable price and good quality. Which shape of a greenhouse is better? The following versions are available:

- Pointed arch. The greenhouse has an impressive area, but a relatively low ceiling. The installation of such a greenhouse is usually done by masters.

- With vertical walls. Famous version of greenhouses. The design is convenient and allows the use of additional shelves. Such greenhouses are characterized by gable roofs. The height and width of the structure determines the convenience of its use. The disadvantage is the likely heat loss from the north.

- The walls are sloping. The greenhouse combines the properties of two previous greenhouses. It is quite convenient if the space is not cluttered with additional racks and shelves.

- Arched type. The robust design is easy to install and use.

- The roof is attic. Comfortable greenhouse with a high roof. It is convenient to place additional devices for growing plants in it.

So how to choose a polycarbonate greenhouse? Gardeners give tips as follows:

- Before purchasing and installing a greenhouse, make a rating among the variations that you liked the most.

- Consider the price of the greenhouse and its installation option. Some facilities can only be mounted by a professional.

Cheap polycarbonate greenhouses

We continue to find out how to choose a polycarbonate greenhouse. The advice of summer residents will help us in this matter. Everyone knows that polycarbonate has an affordable price. There are a huge number of original designs of various sizes and shapes of our own and industrial production.

Polycarbonate of any type is characterized by flexibility, strength, durability, impact resistance and low thermal conductivity. Gardeners know that the price of a greenhouse depends on the quality of the polycarbonate from which the greenhouse is made. Its cost is affected, for example, by the presence of a protective layer from the sun. The price also depends on the color of the coating: it can be red or yellow. It is believed that these colors have a good effect on plant growth.

- an impressive choice

- wear resistance

- affordable price,

- high quality,

- thermal insulation

- plastic,

- flexibility.

The smaller the area of the greenhouse, the lower its price will be. But you do not need to purchase too small greenhouses, as you can’t grow a full and high-quality crop in them.

Greenhouse Reviews

Not sure how to choose a polycarbonate greenhouse? Reviews and advice of experienced gardeners, in order to decide, should be studied first. Quality material is always popular. Polycarbonate greenhouses do not lose their recognition among customers. They are the most famous type of greenhouses, which are successfully implemented on the lands of the whole country.

Such structures are a convenient means for obtaining a crop on a land plot. Over the past year, polycarbonate greenhouses took first place in sales. This means that their owners are happy with their purchases. After all, the durability of such hotbeds far exceeds, for example, the service life of film greenhouses.

Owners like the following:

- moisture resistance

- acceptable price,

- ease of installation

- strength,

- Sun protection,

- reliability,

- durability.

The positive qualities of a greenhouse can be indicated for a long time. Each owner knows that its service life depends on the proper handling of the product. Gardeners advise, after harvesting, to thoroughly clean the greenhouse and prepare for future crops.

Polycarbonate Life Reviews

Many people wonder how to choose a polycarbonate greenhouse. Feedback on the life of this material is provided below. The long service life of a greenhouse is influenced by which company manufactured it, as well as which ones it gave quality guarantees for. And, of course, who uses it and how. Different options have different service life, it all depends on the properties of the material.

Many manufacturers indicate a polycarbonate warranty period of up to 10 years.

Important! Greenhouses for the Urals, Kinovskaya and Severnaya are designed for use in their latitudes.

Choosing a greenhouse must be responsible. No need to save on cheap raw materials, as over time, any investment will pay off. A good greenhouse can last more than 20 years.

Experienced summer residents are advised to look after the greenhouse as follows:

- Clean the cavity of the panels well.

- Replace damaged parts in time.

- Wash surfaces frequently.

- Correctly adjust the pressure of the thermal washers.

The structure must be looked after year-round, but especially after harvesting (in autumn) and when planting (in spring). Gardeners note that you can use any kind of detergent to wash the greenhouse. To implement the process, it is necessary to use only soft sponges, since hard brushes will damage the surface.

Following recommendations

Novice summer residents do not know how to choose a polycarbonate greenhouse. They try to learn the tips and reviews of experienced gardeners as best as possible. When choosing a design for a greenhouse, it is necessary to pay attention to the quality factor of the material from which it is created. It is important to be able to correctly identify its disadvantages and advantages. To do this, you need to learn how to compare various designs.

Summer residents argue that a quality greenhouse must be so strong as to withstand an impressive amount of snow. If it is made from low-quality and thin raw materials, the snow may well deform and even break the roof. You will have to spend a lot of money to replace the old coating, so it is better to immediately buy a quality construction. Of course, it will cost a lot.

How to choose a greenhouse? Be sure to decide which properties will be optimal for applying and installing it in a particular area.

Which greenhouses are better to buy:

- water resistant

- durable

- reliable

- durable

- easy to install

- wear resistant

- UV resistant.

Polycarbonate greenhouses are considered the best for giving. These are durable structures that will last you a long period of time. The best polycarbonate greenhouses should be made by a well-known manufacturer who is ready to provide a guaranteed product life and a quality certificate that you can trust. Summer residents themselves extend the life of the greenhouse by careful maintenance and proper operation.

When purchasing a greenhouse, it is important to take its quality and delivery very seriously. Indeed, before the start of the operational period, materials cannot be damaged.

Today, a huge number of firms and companies are willing to sell polycarbonate greenhouses. When choosing and buying, be sure to pay attention to the name of the manufacturer, his reputation, as well as the legality of his activities. Demand a certificate of quality and a guarantee for this type of product.

Best polycarbonate greenhouses in 2018

Which greenhouses are best to buy in 2018? Everyone knows that a great greenhouse is the key to a smart harvest. Despite the high cost and difficulties with installation, more and more gardeners prefer not to build greenhouses with their own hands, but to buy ready-made versions that take into account all the peculiarities of the Russian climate and designed by craftsmen.

The best arched polycarbonate greenhouses in 2018 are:

- The first place was taken by the Dachnaya-Optima greenhouse (Volia enterprise).

- In second place is the PC Harvest greenhouse.

The best equidistant greenhouses:

- 1st place - “Dubrava” (from Glass House),

- 2nd place - “Royal farm”.

The best cone-shaped greenhouses:

- 1st place - “Dachnaya - Strelka” (from the Volia enterprise),

- 2nd place - “Droplet” (from the company “Orange”).

This rating is based on reviews from real customers.

Top manufacturers

Thinking about which polycarbonate greenhouse to choose? We suggest you study the rating of the best manufacturers of Russia and foreign powers, based on real buyers:

- Volya is a Russian company headquartered in Dubna. The quality of the greenhouses of this trading group is extremely suitable for the natural conditions of the middle zone of the Russian Federation.

- Trading House "Harvest" - the company has grown rapidly since 2004 and has more than 200 retail premises on the lands of the Russian Federation. Knowledgeable employees will tell you which is the best greenhouse to buy and make changes to the drawings based on the personal needs of the client.

- Ready-made hotbed factory “Osnova” - the company owns a large number of branches in Russia, which can be found by a resident of any large city. HRT “Basis” not only creates and designs greenhouses, but also performs assembly and delivery.

- Glass House - Since 2001, the greenhouses of this company have set the tone for innovative developments in the field of structures for summer cottages. The well-known variations from Glass House have no analogues, and the affordable price allows people with any size of wallet to buy them.

Greenhouse frame selection

The frame is a kind of foundation that helps the whole structure to stay. No need to save on materials, otherwise the greenhouse will not stand idle for a long time. Basic materials, their cons and pros are given in the table.

Reliability, ease of assembly, remains unchanged for a long time

Accessibility, lightness, elegance

Breaks under the influence of a strong wind, does not withstand impressive loads

Easy care, lightweight material

Rotting, sags

Low price, environmental friendliness

Summing up, we can say that cheap raw materials turn out to be such only at first glance: in the end, a plastic or aluminum structure will cost much more than a steel one. Continuous repair work to replace failed parts will be needed seasonally, which is unlikely to benefit the family budget.

In addition to the raw materials of the frame arcs, you need to look at the number of arches, the more there are, the longer the greenhouse will last.

What polycarbonate cover greenhouse

Still not sure how to choose the right polycarbonate greenhouse? The advice of gardeners will always help you, do not forget about it. Also study the types of polycarbonate. And they are as follows:

- Cellular polycarbonate is the most famous product for summer cottages on the market, as it has a low cost and excellent thermal insulation qualities, ideal for covering greenhouses. The most popular sheet thickness is 4 mm; a sheet with a thickness of 6 mm will be more durable.

- Monolithic - it is difficult to find it on the store’s counter, although the quality of the material is much higher than that of a cellular one. Almost transparent canvas transmits up to 90% of the light, has high flexibility, easy installation and higher strength. The owner can choose the color of polycarbonate. An important advantage of raw materials is safety for health and environmental friendliness.

- Profiled - a novelty in the Russian market, which has not yet won great popularity. The price of this sheet is identical to the cost of cellular polycarbonate, but the density indicators are close to monolithic. This type of cover for greenhouses has a wavy structure and is used for the roofs of greenhouses.

The choice of polycarbonate to cover the greenhouse depends only on the financial capabilities of the client. If there is enough money, it is better to stop your choice on a monolithic coating.

The best arched greenhouses

What is the best polycarbonate greenhouse? Consider the arched structures. They resemble hemispheres in outline: the fame of the variations of these devices is due to their high resistance to severe natural elements. The absence of angles allows snow to easily roll off the roof, and the spherical shape guarantees resistance to wind.

Based on the above rating, a special place in the hearts of Russian summer residents was won by the Dachnaya-Optima greenhouse from the Volia company. It has high strength: snow easily rolls off a domed roof that can withstand up to 280 kg per m². The frame base is made of galvanized iron profile, the width of each side is 60 mm.

A door is placed at each end - there is no need to go round the greenhouse to get into it. Can't open the doors due to the weather? To ventilate the structure, vents are thought out. The width of the building is typical 3 m, and the length can be chosen - versions of length 6 and 4 m are available. Such a greenhouse with parameters 4 X 3 m costs 19 900 rubles.

- it keeps heat well

- robust construction

- if desired, the structure can be lengthened,

- anticorrosive coating of the profile,

- the structure withstands a layer of snow up to 1.5 m,

- does not require a foundation.

- no tape for sealing,

- intricate assembly

- the kit often lacks bolts and screws.

Consider the PC Harvest Greenhouse. This is a great solution. Despite the low price, the greenhouse has wide functionality and has good parameters. Arched parts are placed at a distance of 65 cm from each other. They provide sufficient rigidity throughout the greenhouse.

Polycarbonate sheets are fastened with ties that do not violate the integrity of the material. The length of the structure can be different - 4.6 and 8 m. If you wish, you can buy an additional section and easily fix it near any element. The average cost of such a greenhouse is 9,000 rubles.

- lasting,

- cheap,

- easy to assemble

- polycarbonate is not damaged during fastening,

- high doors.

- the case is light, strong winds can not stand,

- in winter, the structure can break without backups.

The best equidistant greenhouse

Such structures are good for growing an impressive number of high crops, as they allow you to adjust the height depending on the needs of the owner. These are large greenhouses that require a lot of space on the site. They are difficult to assemble, but the result of labor will exceed all expectations.

The Glass House Dubrava greenhouse is aimed at skilled gardeners. The width of the device is 4 m, while the standard summer cottage has parameters 3 X 3 m. You can choose the length to your liking, but the smallest indicator is also 4 m.

Despite the large volume, greenhouses of this species are very compact. The height of the structure is only 2.8 m, triangular windows for ventilation are installed on the roof.

The frame is equipped with additional screeds, they not only give it rigidity, but are also suitable for installing auxiliary ventilation, heating elements and lighting wiring. The frame can withstand up to 180 kg of snow per 1 m² even when it is covered with cellular polycarbonate. The average construction cost of 4 X 4 m is 47,000 rubles.

- strength,

- compactness

- the ability to grow very tall plants,

- warranty from the manufacturer up to 30 years (applies to the frame),

- galvanized doors, corners and handles.

Best conical greenhouse

This form of the greenhouse allows you to grow very tall plants: it is very convenient to place curly sprouts in structures. In addition, the streamlined shape makes it easy to go snow. As a result, it does not accumulate on the slopes of the roof.

The Dachnaya-Strelka greenhouse from the Volia enterprise took first place in this category of greenhouses. Its drop-shaped form allows you to grow plants up to 2.5 m high. But the advantages of this engineering miracle do not end there.

The greenhouse has high strength. The frame is made of galvanized thick iron and is capable of supporting up to 420 kg! Snowy winters are not afraid of the owner of such a structure. The average price of a greenhouse 2.6 m wide and 4 m long is 23,000 rubles.

- attractive design

- high strength

- simple assembly

- the ability to choose a size (width 3 or 2.6 m),

- reliable manufacturer.

You do not look at the cottage during the winter? Remember that the denser and thicker the polycarbonate, the lower the likelihood of damage to the vegetable "housing". A solid greenhouse will delight the owner not only with an elegant appearance, but also with a significant increase in yield, so you should not save on it.

Types of coating for greenhouses

There are only three types of coverings for greenhouses. All of them are capable of qualitatively performing the main task - to protect plants from environmental damage that is harmful to them.

Coatings are made from:

- polycarbonate

- glass

- plastic film.

Why polycarbonate is good

The most reliable material for greenhouses is polycarbonate. This is a light-transmitting multilayer material, the structure of which in section resembles a honeycomb, which is why it is called cellular.

There is another type of this material - monolithic. But they are not used in the device of greenhouses for the reason that it does not meet all the requirements for these structures.

Important! Monolithic has a significantly greater weight and does not have the light transmittance so necessary for growing the crop. Therefore, it is never considered as a covering material for the frame of the greenhouse.

Cellular polycarbonate, due to its hollow structure, is able to retain heat well. The reason is that in the space between the "cells" is air. It is he who is the best heat accumulator. Therefore, polycarbonate structures are the warmest. For gardeners living in regions with a harsh climate, this is a decisive factor when choosing a greenhouse.

Cellular polycarbonate is a sheet material, but it can be rolled up into rolls that are most convenient for transportation. The diameter of the roll depends on the thickness of the polycarbonate sheet. The thinner it is, the easier it is to roll it. However, even with a 4 mm web thickness, the roll will be quite voluminous - with a diameter of 1.5 to 1.6 m. If you exceed the permissible bending radius, you can damage the structure of the material.

Polycarbonate with a thickness of 4 to 10 mm is suitable for covering greenhouse frames. It should be noted that the thicker the canvas, the greater their weight. Not every frame can withstand the load that a coating of 10 mm polycarbonate will create. Given that in winter it is necessary to add snow load to this indicator, the requirements for the strength and stability of the frame increase many times. The optimal choice for medium-sized greenhouses is 4 or 6 mm polycarbonate.

Table. The main technical characteristics of cellular polycarbonate, which must be considered when choosing.

| Web thickness | Weight (kg / m2) | Light transmittance of a white transparent web (%) | Light transmittance of a white opaque cloth (%) | Light transmission of a color cloth (%) | Thermal Conductivity (W / m2 ° C) |

|---|---|---|---|---|---|

| 4 mm | 0,8 | 82 | 52 | 42 | 3,6 |

| 6 mm | 1,3 | 82 | 58 | 35 | 3,5 |

| 8 mm | 1,5 | 80 | 54 | 35 | 3,3 |

| 10 mm | 1,7 | 76 | 48 | 32 | 2,4 |

The average service life of polycarbonate greenhouses is 15 years. These are the most durable and reliable designs of all existing.

Advantages and disadvantages of glass greenhouses

Glass is an inflexible material, therefore it is suitable only for single-pitched and double-pitched structures. Glass greenhouse is a classic of the genre. It can be easily assembled independently from used materials. Therefore, the main advantage of these designs is budget.

But glass has other advantages that have long been appreciated by gardeners. Greenhouses with such a coating can withstand significant weight loads. Cracked or broken parts can be quickly replaced. The main advantage of glass is its transparency. Plants in such a greenhouse will not suffer from a lack of light.

Important! There are glass greenhouses and "cons". This is fragility, the need for careful handling, fairly high requirements for the strength of the frame.

What is convenient polyethylene tent

The most popular material for covering greenhouses is polyethylene. If earlier the choice was unambiguous (dense polyethylene), today you can choose from several types of this material.

In any store for gardeners, you can find such films:

- light stabilized

- reinforced

- light scattering

- copolymer of ethylene vinyl acetate,

- polyvinyl chloride (cellophane),

- foamed.

Each of these materials can be used to construct a greenhouse and a greenhouse. But when choosing, you need to pay attention to the characteristics. For regions with snowy winters, the best choice is reinforced film.

The Russian market offers products of Turkish, Korean and domestic manufacturers. What is the difference between these materials? Foreign companies produce film with reinforcement made of polyethylene, and Russian - from high-strength polypropylene mesh. Therefore, domestic products are more durable and durable.

The highest light transmittance of a cellophane film. But this material has the least strength of all the others, therefore it is suitable only for temporary or annual structures.

The stabilized film is able to reflect heat inside a greenhouse or greenhouse. This property is taken into account when arranging shelters for seedlings. Antifog, which is part of the film, prevents the formation of condensation on the outer surface of the tent.

The light scattering film is capable of reflecting UV and IR rays. This ensures the maximum possible protection of plants from the negative effects of the environment. The phosphors included in the film make it possible to obtain uniform illumination of the interior of the greenhouse.

The strongest of the films is copolymer. It perfectly withstands wind speeds of 18-20 m / s. Another of its advantages is frost resistance. The copolymer film does not crack at temperatures up to -80 ° C, so this material is chosen for the construction of greenhouses in areas with a cold and windy climate.

The foamed film is two-layer. One layer is dense and smooth, the second is porous. The space in the cells of the second layer is filled with air. Therefore, the foamed film has a sufficiently low thermal conductivity. This is an important indicator for greenhouses. But this material also has its drawback: low light transmission. Therefore, foamed film is chosen for sheltering in areas with a large number of sunny days.

Frameworks of greenhouses

Frameworks for greenhouses are made of steel and aluminum. When making improvised structures, wooden bars are often used. What should I look for when choosing the material from which the frame is made?

- For the presence of a protective coating on steel frames. If it is absent, already in the second year of operation of the greenhouse, it will be possible to notice the first signs of rust. This design will not last long. Frames of this type are mainly made of galvanized steel.

Many manufacturers offer greenhouses with frames painted with powder paints. This is a good solution to ensure durability. Regardless of the method of metal processing, aluminum frames are almost two times more expensive than steel. This is due to the lighter weight of the former and their maximum resistance to corrosion.

However, aluminum frames have one significant drawback. Frames of this material are unable to withstand significant weight loads from the severity of certain types of coating, as well as from snow. Therefore, in the spring it is often possible to see greenhouses overwintered on a site, whose racks are curved. This suggests that the owner did not take into account when choosing the design of the climatic features of his region.

Types of frame structures

There are two main types of greenhouse frame structures:

The former are optimal for those who are often in the country, and regardless of the season. Collapsible structures are chosen by those gardeners who visit their site only in the warm season. In this case, it makes sense to buy exactly those greenhouses that can be dismantled and stored before the start of the next season. Thus, it will be possible not to fear for the safety of their property.

Price and quality

The most affordable - small in area (up to 5 m 2) greenhouses with a polyethylene awning and a steel frame painted with powder dye - 8-10 thousand rubles. The same structures, but with a polycarbonate coating, will cost about 50% more - up to 15 thousand rubles. The most expensive are glass greenhouses. These structures are mounted only on the basis of reliable steel frames. A glass greenhouse with an area of up to 5 m 2 will cost a little more than 20 thousand rubles.

The price depends on various parameters - in particular, on:

- the presence or absence of windows for ventilating the interior of the greenhouse,

- number of doors

- thickness and type of coating

- frame material

- forms of construction.

Polycarbonate greenhouses are considered the most practical and high-quality. They are almost 200 times stronger and more reliable than glass. The least number of positive reviews about plastic greenhouses. They serve, as a rule, no more than 1-2 summer seasons.

Forms of greenhouses

Greenhouses can be absolutely any shape, length and configuration. Frameworks of stationary structures are made as follows: steel profiles are welded together and reinforce corners and joints. All manufacturers of greenhouses offer the service of manufacturing these products according to the size and designs of the customer. Therefore, it is not difficult to obtain a design of exactly the shape and dimensions that are needed.

Arched type greenhouses

The arched shape is most successful for several reasons.

- It does not form a high layer of snow. This ensures the safety of the covering material.

- Arched form involves a minimum number of seams and joints. This gives the design the greatest reliability in operation.

- Greenhouses of this form are resistant to winds.

- Finally, such designs are easy to install and can easily be extended in length.

But in spite of everything, arched structures cannot be called perfect. They also have their drawbacks. The main one is less internal space than rectangular greenhouses. Another disadvantage is that for structures more than 2 meters high, installation of reinforcing beams is required.

Polycarbonate greenhouse: material features

Polycarbonate has won the love and trust of many summer residents. Nevertheless, not all of them understand what kind of material this is, understands its structure and features. Let’s try to open this question if possible.

Material polycarbonate - has honeycomb structure. The honeycombs of which it consists are filled with air, which helps to retain heat. Sheets of cellular polycarbonate are treated with special varnishes, so that the material does not transmit harmful ultraviolet radiation.

Material polycarbonate - has honeycomb structure. The honeycombs of which it consists are filled with air, which helps to retain heat. Sheets of cellular polycarbonate are treated with special varnishes, so that the material does not transmit harmful ultraviolet radiation.

Polycarbonate is easy to process. It can be drilled, glued and welded without any problems. You can cut the material with jigsaw, or, in its absence, with reinforced scissors.

The main technical properties polycarbonate: it is very light, perfectly transmits sunlight and retains heat at the same time. The material is flexible and plastic, which makes working with it easy and comfortable. The polycarbonate greenhouse can be equipped with window panes or partitions without any problems.

The choice of material for the greenhouse

When choosing polycarbonate for your greenhouse, you should pay attention to two parameters of this material: color and thickness. The thicker the polycarbonate sheet is, the better. In general, an ideal option would be to choose a coating in two layers. Polycarbonate possesses good qualities with the presence of an internal special layer, which prevents the appearance of condensate on the inner walls of the greenhouse.

When choosing polycarbonate for your greenhouse, you should pay attention to two parameters of this material: color and thickness. The thicker the polycarbonate sheet is, the better. In general, an ideal option would be to choose a coating in two layers. Polycarbonate possesses good qualities with the presence of an internal special layer, which prevents the appearance of condensate on the inner walls of the greenhouse.

As for the color of the material, it also matters, and it all depends on what particular plants will be grown in the greenhouse. If the plans include growing a wide assortment of vegetables, then obviously it’s worth choosing not color, but white transparent polycarbonate.

Polycarbonate greenhouse: advantages and disadvantages

More traditional materials for creating greenhouses are glass and polyethylene. Comparing a polycarbonate structure with such greenhouses, perhaps the main advantage is its durability.If a polycarbonate greenhouse has appeared on your summer cottage - you can no longer worry, it will last you decades.

In addition, the design of such a greenhouse is easy you can mount it yourselfwithout asking for help from specialists.

The cost of polycarbonate greenhouses is different, depending on the size of the greenhouse itself and the quality of the feedstock. Such wide price range will allow any summer resident to choose for themselves the option that will correspond to its financial capabilities.

So, the following are the main advantages of polycarbonate greenhouses:

they have maximum bandwidth of sunlight

they have maximum bandwidth of sunlight- such greenhouses are very resistant to mechanical damage,

- due to the plasticity of the material, the greenhouse can be given any form

- Polycarbonate greenhouse reaches service life 20 years,

- polycarbonate greenhouses are resistant to water and moisture,

- the design of such a greenhouse has attractive appearance.

In addition to these advantages, polycarbonate greenhouses have their own limitations, among which:

- flammability of the material, when exposed to open flame, the material will melt,

- relatively high price for polycarbonate greenhouses (compared to prices for greenhouses made of other materials).

Choosing a finished polycarbonate greenhouse

It may seem to many that the easiest way is to purchase a ready-made polycarbonate greenhouse design. However, few people know that finished greenhouses have their drawbacks.

The first is instability finished construction. Therefore, it will be necessary to take additional care of a reliable foundation. Secondly, finished greenhouses have, as a rule, full (through) transparency. Thus, sunlight penetrating the greenhouse through one wall will also pass freely through the other. Thirdly, the frame of finished structures is often very susceptible to corrosion.

Despite all these problems, it’s clear that installing a finished greenhouse is much easier than doing it yourself. The manufacturer will manufacture all parts and elements of the greenhouse with accuracy, which is essential facilitate the assembly process designs. How to choose a finished polycarbonate greenhouse?

Despite all these problems, it’s clear that installing a finished greenhouse is much easier than doing it yourself. The manufacturer will manufacture all parts and elements of the greenhouse with accuracy, which is essential facilitate the assembly process designs. How to choose a finished polycarbonate greenhouse?

Many may think that all the designs of polycarbonate greenhouses are the same, but this is not so. By choosing a greenhouse at a lower cost, you can significantly miscalculate as designs and get, therefore, a number of unnecessary problems.

Therefore, you need to choose greenhouses from trusted and quality manufacturers. When buying a finished greenhouse, you should pay attention to ease of assembly design, as well as the availability of accessible and informative instructions for it.

DIY polycarbonate greenhouse construction

If you decide to build a greenhouse yourself, then it should be noted that in this case the greenhouse will cost you less.

The cost of the greenhouse will depend, first of all, on construction dimensions. So, for example, a polycarbonate greenhouse with a height and width of 3.5 meters and a length of 4.5 meters will cost an average of 50 thousand rubles. Obviously, with the increase in the size of the greenhouse, its price will increase. So, a greenhouse six meters long will cost about 65 thousand rubles, and greenhouses eight meters long - already about 80 thousand rubles.

The cost of the greenhouse will also be determined quality and durability selected material. So, according to the strength parameter, all greenhouses can be divided into three groups:

- standard strength

- guaranteed strength

- titanic strength.

Foundation laying

In order for the entire construction of the greenhouse to stand reliably, you need to start with laying a quality foundation. You can use FBS blocks or lay a strip foundation with the following parameters: width - 20 centimeters, depth - 50 centimeters. Application of the second option will give you a more reliable and durable foundation. Having laid the foundation, we can proceed to the installation of the arch frame of the future greenhouse.

In order for the entire construction of the greenhouse to stand reliably, you need to start with laying a quality foundation. You can use FBS blocks or lay a strip foundation with the following parameters: width - 20 centimeters, depth - 50 centimeters. Application of the second option will give you a more reliable and durable foundation. Having laid the foundation, we can proceed to the installation of the arch frame of the future greenhouse.

Frame mounting

For the frame of the greenhouse, it is best to take galvanized profile. From it you need to collect T-shaped elements and attach them to the foundation with self-tapping screws. When constructing the frame, it is important that calculate the pitch of the transverse crate and longitudinal supports of the greenhouse. Stiffeners can provide additional stability to the entire structure in case of heavy precipitation or strong winds. When constructing the frame of the greenhouse, it is worth providing a place for the front door, as well as window leaves.

The material for the frame of the greenhouse can be regular metal profile. However, to protect it from corrosion, it will have to be treated with a special primer.

Greenhouse assembly

For a standard size greenhouse (6 meters long) you will need about four sheets of polycarbonate. Cutting Polycarbonate Panels is Best jigsaw, while it is necessary to take into account the bending radius of the arched elements, the width of the strips along the stiffeners.

For a standard size greenhouse (6 meters long) you will need about four sheets of polycarbonate. Cutting Polycarbonate Panels is Best jigsaw, while it is necessary to take into account the bending radius of the arched elements, the width of the strips along the stiffeners.

After the polycarbonate blanks are ready, they need to be inserted into the grooves of the profile and fixed with screws, using thermowells. They will save material from deformations in place of fixture. The step between the attachment points should not exceed 400 millimeters.

To seal joints, from the inside of the sheets you need to use a perforated tape, and from the outside - self-adhesive aluminum tape. To prevent condensation from accumulating on the inside of the panels, drill holes in the profile.

Owner reviews

Thus, a polycarbonate greenhouse is wonderful decision for growing healthy and tasty fruits and vegetables. Thanks to the presence of such a greenhouse in the country, you can get the crop almost all year round! Finally, it is worth reading a few reviews about polycarbonate greenhouses from those summer residents who already have experience in their operation.

We have a polycarbonate greenhouse for two years and survived two cold winters. For greater reliability, we reinforced it with two additional supports in the middle of the structure. Greens and cucumbers - were very early. And even now, despite the cold autumn weather, tomatoes and bell peppers continue to sing in the greenhouse.

He installed a factory polycarbonate greenhouse in his country house in 2011. I thought it would be more reliable this way, but the greenhouse didn’t survive the second winter: all arcs have broken. The manufacturer company refused to repair the structure, citing the fact that this is not a warranty case. Once again I was convinced of what I did with my own hands - this is for centuries.

My polycarbonate greenhouse has been in my fourth year, and no problem! From early spring I grow seedlings there and until late autumn - various flowers. I advise everyone to choose a greenhouse design with a rigid frame made of galvanized steel. Polycarbonate for our region is better to choose a thickness of 6 millimeters. And be sure to lay a reliable one under the greenhouse strip foundation.

they have maximum bandwidth of sunlight

they have maximum bandwidth of sunlight